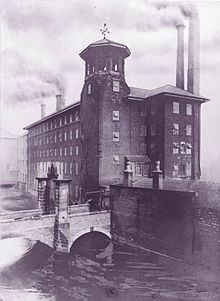

Lombe's Mill

John Lombe had visited the successful silk throwing mill in Piedmont in 1716, an early example of industrial espionage.

He designed the mill, and with his half-brother Thomas Lombe (born 1685) instructed George Sorocold to build it and fit it with the new machines.

John Lombe's idea of mill was inspired by contemporary smaller and less effective mills he studied during the period in which he worked in Italy: traditionally the spinning wheel was used for producing small quantities of silk thread at the homes of local spinsters, the new machines were capable of producing far greater quantities of silk and provided serious competition for the Italians.

The King of Sardinia reacted badly to the commercial challenge, placing an embargo on the export of raw silk.

Wilson remained in Leeds leaving the running of the mill to his partners, William and Samuel Lloyd, both London merchants, with Thomas Bennet as manager, taking a proportion of the profits.

Together with the single source of power (water), and the large size and organisation of the workforce for the period (200–400, according to contemporary sources), the total process of production from raw silk to fine quality thread has led the Lombes' silk mill to be described as the first successful use of the factory system in Britain.

Work only stopped in time of drought, extreme frost or problems with the silk supply, although unofficial holidays were taken during elections and Derby races in August 1748.

In 1765 Thomas Bennet bought the premises from Lloyd subject to a mortgage to the Wilson family but neglected the building during years of trade recession and competition from other mills in Derby and Cheshire.

Lamech Swift became the sub-tenant in 1780 paying an annual rent of £7 to the corporation and £170 to Thomas Wilson, brother of Richard and William.

Torrington commented on the "heat, stinks and noise", whilst Fairholt in 1835 was appalled by the sickly appearance of the poor children.

November 1833 saw the beginning of industrial unrest in Derby which led to the formation of the Grand National Trades Union in February 1834.

This event is commemorated by a march organised by the Derby Trades Union Council[6] annually on the weekend before MayDay.

This was first screened at Derby Quad cinema on 25 April 2015[8] The Taylor family remained in occupation of the mill until 1865 when bankruptcy forced them to sell the machinery and lease.

"The Derby Mercury" advertised several silk mills for sale that year when a general slump hit the industry.

This took place four years before the Cobden Treaty with France which is said to have effectively destroyed the British silk industry.

Great efforts were made by the borough fire brigade and the Midland Railway Company who saved the shell of the tower and the outline of the doorways leading into the original five floors.

In 1700 the favoured silk was produced by a moth (Bombyx mori), that spun a cocoon to protect the larvae.

Silk fibres from the Bombyx mori silkworm have a triangular cross section with rounded corners, 5–10 μm wide.

The cocoons were harvested and placed in troughs of hot water to dissolve the gum and allowed the single thread to be wound into a skein.

[1] In 1700, Italians were the most technologically advanced throwsters in Europe and had developed two machines capable of winding the silk onto bobbins while putting a twist in the thread.