MPDS4

The system's history is closely tied to the very beginnings of mainstream CAD and the research culture fostered by Cambridge University and the UK government including the resulting "Cambridge Phenomenon "[1] MPDS was initially developed for 3D plant design and layout and piping design.

CIS had developed an electrical cabling solution initially called CABLOS, which Dowty Engineering first purchased in about 1979.

To facilitate this work, the baCIS 2 interpretive language and the MDB relational database were developed for MPDS.

The company, which also provided add-on modules and customizations, had established a development relationship first with ComputerVision, then with PTC.

The development partnership between Quintic and CAD Schroer strengthened, as the two companies worked to create a Fourth Generation release of MEDUSA and MPDS.

This included a complete overhaul of the functionality; the development of a graphical user interface (GUI) based on the Qt (framework) technology, the development of data exchange mechanisms and interfaces with third party systems, and the porting to the Linux open-source operating system.

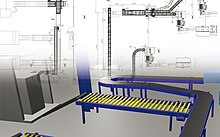

Because 3D plant models can be generated from catalog-based drawing routines, the demand on computer memory and resources is limited.

Plants of hundreds of thousands of components can be designed, edited and exported to a compact .HSF format for external visual review.

Central user administration and access controls in MPDS allow Administrators to set up a variety of users who can work on a plant design simultaneously, and who can have different access privileges - limited, for example, to certain design disciplines or to certain areas within a plant.

MPDS4 includes hard and soft clash detection, which can be applied to a whole project, to separate systems or between selected components.

Results can be passed to customizable reports, and components used in a design are automatically included in parts lists.