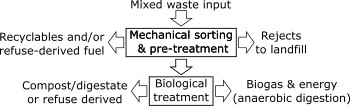

Mechanical biological treatment

This either removes recyclable elements from a mixed waste stream (such as metals, plastics, glass, and paper) or processes them.

It typically involves factory style conveyors, industrial magnets, eddy current separators, trommels, shredders, and other tailor made systems, or the sorting is done manually at hand picking stations.

RDF can be used in cement kilns or thermal combustion power plants and is generally made up from plastics and biodegradable organic waste.

In the case of biodrying, the waste material undergoes a period of rapid heating through the action of aerobic microbes.

Alternatively a partial anaerobic digestion phase can be induced on water that is percolated through the raw waste, dissolving the readily available sugars, with the remaining material being sent to a windrow composting facility.

By processing the biodegradable waste either by anaerobic digestion or by composting MBT technologies help to reduce the contribution of greenhouse gases to global warming.

Alternatively MBT solutions can diminish the need for home separation and kerbside collection of recyclable elements of waste.

This gives the ability of local authorities, municipalities and councils to reduce the use of waste vehicles on the roads and keep recycling rates high.