Mikoyan-Gurevich I-250

While quite successful when it worked, with a maximum speed of 820 km/h (510 mph) being reached during trials, production problems with the VRDK fatally delayed the program and it was canceled in 1948 as obsolete.

As a result of this meeting the NKAP ordered the Lavochkin, Sukhoi, Yakovlev and Mikoyan-Gurevich design bureaus (OKBs) to develop and build jet aircraft with the utmost dispatch.

Aware of earlier problems encountered with other novel propulsion systems such as ramjets both Sukhoi and Mikoyan-Gurevich chose to use the VRDK booster engine that had been under development since 1942.

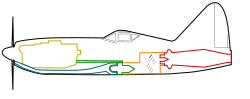

After takeoff a clutch at the end of the crankshaft could be engaged which drove a step up gearbox with a ratio of 13:21 to an extension shaft that powered the compressor of the VRDK.

The air for the compressor was fed through a long duct that ran from the inlet underneath the propeller spinner, thence under the engine and through the belly of the aircraft.

This duct also fed air to the oil cooler near the engine, but the water radiator was positioned behind the compressor to maximize airflow over it.

However the VRDK was limited to only ten minutes' operating time per sortie, which meant that it was useless weight during the rest of the flight.

Other than the VRDK the aircraft was largely conventional in layout, although the cockpit was set very far back in the fuselage, almost to the base of the vertical tail.

To assist Mikoyan TsAGI was ordered to provide help with aerodynamic and stress calculations and to test a full-size mockup in their wind tunnel in one month's time.

TsIAM was ordered to deliver three VRDK engines with 9-kilonewton (2,000 lbf) at 7,000 m (22,966 ft) with a specific fuel consumption of 1,200 kg (2,600 lb) per hour.

A mock-up was inspected on 26 October and rejected because of the poor cockpit layout, although this decision was reversed because the fuselage of the first prototype was too far along for major changes that would have significantly delayed the program.

The first prototype was grounded for most of June to remedy magneto problems and to add extra air intakes to cool the spark plugs.

The pilot complained of excess torque pull to the right so the vertical stabilizer was enlarged by 0.63 m2 (6.8 sq ft), but this was just one of numerous problems, and it was not ready to pass State acceptance trials without more development work on the powerplant.

However, the second prototype continued flight testing until 12 July 1946 when an engine fire forced an emergency landing and it was damaged beyond repair.

He refused to accept its findings as it apportioned blame fairly evenly among those responsible for the production program and he had the director of Factory No.

The first I-250 was finally accepted on 8 August and flown for the first time three days later, although its engine seals failed and a number of ignition cables were scorched.