Nondestructive testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage.

[2] Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research.

Visual inspection (VT), the most commonly applied NDT method, is quite often enhanced by the use of magnification, borescopes, cameras, or other optical arrangements for direct or remote viewing.

Another commonly used NDT method used on ferrous materials involves the application of fine iron particles (either suspended in liquid or dry powder – fluorescent or colored) that are applied to a part while it is magnetized, either continually or residually.

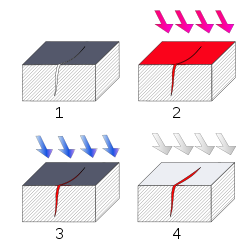

This method (liquid penetrant testing) (PT) involves using dyes, fluorescent or colored (typically red), suspended in fluids and is used for non-magnetic materials, usually metals.

Detecting the failure can be accomplished using a sound detector or stress gauge which produces a signal to trigger the high-speed camera.

Nondestructive testing methods are routinely applied in industries where a failure of a component would cause significant hazard or economic loss, such as in transportation, pressure vessels, building structures, piping, and hoisting equipment.

Differences may indicate an inappropriate model (which may alert engineers to unpredicted instabilities or performance outside of tolerances), failed components, or an inadequate control system.

Reference standards, which are structures that intentionally flawed in order to be compared with components intended for use in the field, are often used in NDT.

Technological improvements or upgrades in these NDT methods have migrated over from medical equipment advances, including digital radiography (DR), phased array ultrasonic testing (PAUT), and endoscopy (borescope or assisted visual inspection).

(Basic source for above: Hellier, 2001) Note the number of advancements made during the WWII era, a time when industrial quality control was growing in importance.

Successful and consistent application of nondestructive testing techniques depends heavily on personnel training, experience and integrity.

[37] In America it is based mostly on the Aerospace Industries Association's (AIA) AIA-NAS-410 [38] and in the European Union on the equivalent and very similar standard EN 4179.

[24] However EN 4179:2009 includes an option for central qualification and certification by a National aerospace NDT board or NANDTB (paragraph 4.5.2).

[40][41] Guidelines for correct application of statistical methods to POD tests can be found in ASTM E2862 Standard Practice for Probability of Detection Analysis for Hit/Miss Data and MIL-HDBK-1823A Nondestructive Evaluation System Reliability Assessment, from the U.S. Department of Defense Handbook.

- Section of material with a surface-breaking crack that is not visible to the naked eye.

- Penetrant is applied to the surface.

- Excess penetrant is removed.

- Developer is applied, rendering the crack visible.