OLED

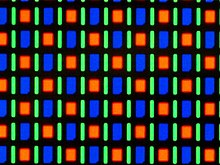

OLEDs are used to create digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles.

They applied high alternating voltages in air to materials such as acridine orange dye, either deposited on or dissolved in cellulose or cellophane thin films.

[9][10][11][12] In 1960, Martin Pope and some of his co-workers at New York University in the United States developed ohmic dark-injecting electrode contacts to organic crystals.

[citation needed] Research into polymer electroluminescence culminated in 1990, with J. H. Burroughes at the Cavendish Laboratory at Cambridge University, UK, reporting a high-efficiency green light-emitting polymer-based device using 100 nm thick films of poly(p-phenylene vinylene).

[citation needed] The decay of this excited state results in a relaxation of the energy levels of the electron, accompanied by emission of radiation whose frequency is in the visible region.

Decay from triplet states (phosphorescence) is spin forbidden, increasing the timescale of the transition and limiting the internal efficiency of fluorescent OLED emissive layers and devices.

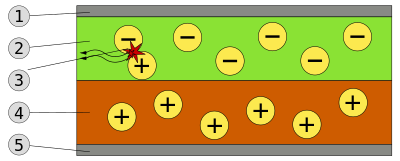

Experimental research has proven that the properties of the anode, specifically the anode/hole transport layer (HTL) interface topography plays a major role in the efficiency, performance, and lifetime of organic light-emitting diodes.

Imperfections in the surface of the anode decrease anode-organic film interface adhesion, increase electrical resistance, and allow for more frequent formation of non-emissive dark spots in the OLED material adversely affecting lifetime.

Possible examples include single crystal sapphire substrates treated with gold (Au) film anodes yielding lower work functions, operating voltages, electrical resistance values, and increasing lifetime of OLEDs.

For example, electron only devices can be obtained by replacing ITO with a lower work function metal which increases the energy barrier of hole injection.

An example of using exciplex is grafting Oxadiazole and carbazole side units in red diketopyrrolopyrrole-doped Copolymer main chain shows improved external quantum efficiency and color purity in no optimized OLED.

[40] Molecules commonly used in OLEDs include organometallic chelates (for example Alq3, used in the organic light-emitting device reported by Tang et al.), fluorescent and phosphorescent dyes and conjugated dendrimers.

Because of the structural flexibility of small-molecule electroluminescent materials, thin films can be prepared by vacuum vapor deposition, which is more expensive and of limited use for large-area devices.

The vacuum coating system, however, can make the entire process from film growth to OLED device preparation in a controlled and complete operating environment, helping to obtain uniform and stable films, thus ensuring the final fabrication of high-performance OLED devices.However, small molecule organic dyes are prone to fluorescence quenching[58] in the solid state, resulting in lower luminescence efficiency.

Therefore, the development of devices based on small-molecule electroluminescent materials is limited by high manufacturing costs, poor stability, short life, and other shortcomings.

If the polymeric OLED films are made by vacuum vapor deposition, the chain elements will be cut off and the original photophysical properties will be compromised.

The heavy metal atom at the centre of these complexes exhibits strong spin-orbit coupling, facilitating intersystem crossing between singlet and triplet states.

In the case of OLED, that means the cavity in a TEOLED could be especially designed to enhance the light output intensity and color purity with a narrow band of wavelengths, without consuming more power.

The use of a microcavity in top-emission OLEDs with color filters also contributes to an increase in the contrast ratio by reducing the reflection of incident ambient light.

IJE solvents are commonly organic instead of water-based due to their non-acidic nature and ability to effectively dissolve materials at temperatures under the boiling point of water.

[147][148][149] Since 2012, research focuses on organic materials exhibiting thermally activated delayed fluorescence (TADF), discovered at Kyushu University OPERA and UC Santa Barbara CPOS.

[171] OLED technology can also be found in digital media players such as the Creative ZEN V, the iriver clix, the Zune HD and the Sony Walkman X Series.

[183] On 31 October 2018, Royole, a Chinese electronics company, unveiled the world's first foldable screen phone featuring a flexible OLED display.

[206] On 8 January 2013, at CES Samsung unveiled a unique curved 4K Ultra S9 OLED television, which they state provides an "IMAX-like experience" for viewers.

[220][221] In July 2008, a Japanese government body said it would fund a joint project of leading firms, which is to develop a key technology to produce large, energy-saving organic displays.

[222] In October 2008, Sony published results of research it carried out with the Max Planck Institute over the possibility of mass-market bending displays, which could replace rigid LCDs and plasma screens.

Eventually, bendable, see-through displays could be stacked to produce 3D images with much greater contrast ratios and viewing angles than existing products.

[225] On 17 February 2011, Sony announced its 25" (63.5 cm) OLED Professional Reference Monitor aimed at the Cinema and high end Drama Post Production market.

[244] The monitor was announced to feature a 30-inch (76 cm) 4K UHD OLED panel with a 120 Hz refresh rate, 0.1 millisecond response time, and a contrast ratio of 400,000:1.

Reports suggested that Dell canceled the monitor as the company was unhappy with the image quality of the OLED panel, especially the amount of color drift that it displayed when viewed from the sides.