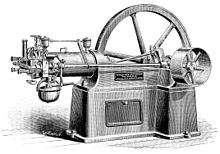

Otto engine

Three types of internal combustion engines were designed by German inventors Nicolaus Otto and his partner Eugen Langen.

In his travels he encountered the internal combustion engine built in Paris by Belgian expatriate Jean Joseph Etienne Lenoir.

In testing a replica of the Lenoir engine in 1861 Otto became aware of the effects of compression on the fuel charge.

In competition at the 1867 World's Fair in Paris, it easily bested the efficiency of the Lenoir engine and won the gold medal, thus paving the way for production and sales which funded additional research.

The atmospheric engine used a gas flame ignition system and was made in output sizes from 0.25 to 3 hp (0.19 to 2.24 kW; 0.25 to 3.04 PS).

[4] After 14 years of research and development Otto succeeded in creating the compressed charge internal combustion engine May 9, 1876.

This resulted in controlled combustion and a longer push of the piston in the cylinder rather than the explosion which destroyed all the engines attempted previously.

Otto turned his attention to the 4-stroke cycle largely due to the efforts of Franz Rings and Herman Schumm, brought into the company by Gottlieb Daimler.

This work was conducted in parallel to the work of Gottlieb Daimler and Wilhelm Maybach who also developed a carburetor which replaced the original hot tube ignition on the Daimler Reitwagen, and a magneto ignition system which formed the basis of the magneto of the Robert Bosch Corporation.

This usually consisted of a pivoting trip-arm that briefly grabs a power switch lever and gives it a quick pull.

The switch lever is then released and allowed to snap back to its original position in preparation for the next cycle.

Rather than tripping a switch, the spark plug firing arm applies a quick rotation to the magneto rotor, which then snaps back under spring tension.

This quick rotation of the magneto coil produces a very brief current flow that fires the spark plug and ignites the fuel.

This design has the advantage of requiring no external battery, and is how modern portable gas engines operate, incorporating the magnet portion of the magneto into the flywheel.

The spinning balls are the centrifugal governor, and as the machine runs slower the small wheel moves to the left, inserting the rod into the nearby roller and pushing it up to trigger the intake of fuel to fire the engine for one revolution.

If the machine is under load and still running too slowly, the cam continues to stay inserted and makes the engine fire repeatedly for each ignition cycle.

The stationary Otto engines on display at the Western Minnesota Steam Threshers Reunion all share a single large heat radiator outside the building.

[9] In 1885, Daimler and Maybach created the "Grandfather Clock" engine, partly inspired by Otto's ideas, and built a two-wheeled frame around it.

[12] Deutz continued to produce large stationary engines, while Daimler moved onto boats, airships, locomotives, automobiles, trucks, and other transportation uses.