Tube bending

These processes can be used to form complex shapes out of different types of ductile metal tubing.

[1] Freeform-bending processes, like three-roll-pushbending, shape the workpiece kinematically, thus the bending contour is not dependent on the tool geometry.

Often, stock tubing is held firmly in place while the end is rotated and rolled around the die.

Other forms of processing including pushing stock through rollers that bend it into a simple curve.

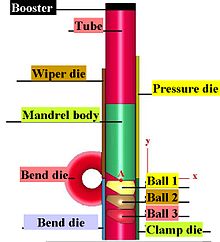

The tube is held in tension by a wiper die to prevent any creasing during stress.

A wiper die is usually made of a softer alloy such as aluminum or brass to avoid scratching or damaging the material being bent.

However, when there is a concern of scratching or gouging the work piece, a softer material such as aluminum or bronze is utilized.

Although a single die can produce various shapes, it only works for one size tube and radius.

Rotary draw benders are the most popular machines for use in bending tube, pipe and solids for applications like: handrails, frames, motor vehicle roll cages, handles, lines and much more.

Rotary draw benders create aesthetically pleasing bends when the right tooling is matched to the application.

For relatively easy bending processes (that is, as the difficulty factor BF decreases), the tooling can be progressively simplified, eliminating the need for the axial assist, the mandrel, and the wiper die (which mostly prevents wrinkling).

Furthermore, in some particular cases, the standard tooling must be modified in order to meet specific requirements of the products.

This process is suited to producing coils of pipe as well as long gentle bends like those used in truss systems.

To change the bending plane, the pusher rotates the tube around its longitudinal axis.

Generally, a TRPB tool kit can be applied on a conventional rotary draw bending machine.

Induction bending is used to produce bends for a wide range of applications, such as (thin walled) pipe lines for both the upstream and down stream and on- and off shore segments of the petrochemical industry, large radius structural parts for the construction industry, thick walled, short radius bends for the power generating industry and city heating systems.

Big advantages of induction bending are: The pipe is filled with a water solution, frozen, and bent while cold.

A form type tapers the end of the mandrel to provide more support in the bend of the tube.

The conjoined ball-like disks are inserted into the tubing to allow for bending while maintaining the same diameter throughout.