Plough

[3] The prime purpose of ploughing is to turn over the uppermost soil,[4] bringing fresh nutrients to the surface[5] while burying weeds and crop remains to decay.

The modern word comes from the Old Norse plógr, and is therefore Germanic, but it appears relatively late (it is not attested in Gothic) and is thought to be a loan from one of the north Italic languages.

Finally, Vladimir Orel (2003)[14] tentatively attaches plough to a PIE stem *blōkó-, which supposedly gave Old Armenian peɫem "to dig" and Welsh bwlch "crack", though the word may not be of Indo-European origin.

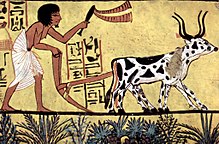

[4] These were used in highly fertile areas, such as the banks of the Nile, where the annual flood rejuvenates the soil, to create drills (furrows) in which to plant seeds.

Hoe-farming is the traditional tillage method in tropical or sub-tropical regions, which are marked by stony soils, steep slope gradients, predominant root crops, and coarse grains grown at wide intervals.

Some ancient hoes, like the Egyptian mr, were pointed and strong enough to clear rocky soil and make seed drills, which is why they are called hand-ards.

However, domestication of oxen in Mesopotamia and the Indus Valley Civilisation, perhaps as early as the 6th millennium BC, provided mankind with the draft power needed to develop the larger, animal-drawn true ard (or scratch plough).

The ard does not clear new land well, so hoes or mattocks had to be used to pull up grass and undergrowth, and a hand-held, coulter-like ristle could be made to cut deeper furrows ahead of the share.

The heavy iron moldboard plow was invented in China's Han Empire in the 1st and 2nd century, and from there it spread to the Netherlands, which led the Agricultural Revolution.

The mould-board plough greatly reduced the time needed to prepare a field and so allowed a farmer to work a larger area of land.

In areas where snow build-up causes difficulties, this lets farmers plant the soil earlier, as the meltwater run-off drains away more quickly.

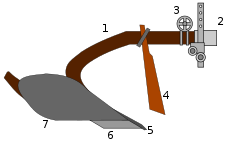

[4] It is responsible for lifting and turning the furrow slice and sometimes for shattering it, depending on the type of mould board, ploughing depth and soil conditions.

To suit different soil conditions and crop requirements, mould boards have been designed in different shapes, each producing its own furrow profile and surface finish, but essentially they still conform to the original plough body classification.

[citation needed] An advance on the basic design was the iron ploughshare, a replaceable horizontal cutting surface mounted on the tip of the share.

The re-set mechanism allows each body to move rearward and upward to pass without damage over obstacles such as rocks hidden below soil surface.

A heavy leaf or coil-spring mechanism that holds the body in its working position under normal conditions resets the plough after the obstruction is passed.

[citation needed] Manual loy ploughing was a form used on small farms in Ireland where farmers could not afford more, or on hilly ground that precluded horses.

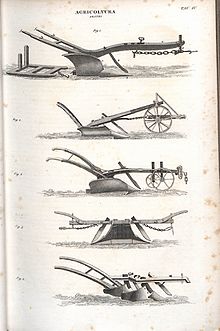

The introduction of wheels to replace the runner allowed the weight of the plough to increase, and in turn the use of a larger mould-board faced in metal.

[45] In 1789 Robert Ransome, an iron founder in Ipswich, started casting ploughshares in a disused malting at St Margaret's Ditches.

Using mathematical methods, he eventually arrived at a shape cast from a single piece of iron, an improvement on the Scots plough of James Anderson of Hermiston.

This was again improved on by Jethro Wood, a blacksmith of Scipio, New York, who made a three-part Scots plough that allowed a broken piece to be replaced.

[48] Then in 1837 John Deere introduced a steel plough; it was so much stronger than iron designs that it could work soil in US areas previously thought unsuitable for farming.

Reversible ploughs may either be mounted or semi-mounted and are heavier and more expensive than right-handed models, but have the great advantage of leaving a level surface that facilitates seedbed preparation and harvesting.

[52] John Deere, an Illinois blacksmith, noted that ploughing many sticky, non-sandy soils might benefit from modifications in the design of the mould board and the metals used.

It does not work as well as a mould-board plough (but this is not seen as a drawback, because it helps to fight wind erosion), but it does lift and break up the soil (see disc harrow).

[citation needed] The chisel plough is a common tool for deep tillage (prepared land) with limited soil disruption.

It is found in Shetland, some western crofts, and more rarely Central Scotland, typically on holdings too small or poor to merit the use of animals.

Similar machines, so-called pipe-and-cable-laying ploughs, are even used under the sea for laying cables or for preparing the earth for side-scan sonar in a process used in oil exploration.

The para-plough, or paraplow, loosens compacted soil layers 3 to 4 dm (12 to 16 inches) deep while maintaining high surface residue levels.

Typically, farmers break that up with a subsoiler, which acts as a long, sharp knife slicing through the hardened layer of soil deep below the surface.