Shed

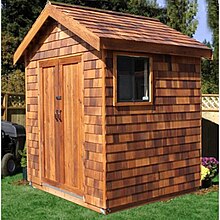

Sheds vary considerably in their size and complexity of construction, from simple open-sided ones designed to cover bicycles or garden items to large wood-framed structures with shingled roofs, windows, and electrical outlets.

Small sheds may include a wooden or plastic floor, while more permanent ones may be built on a concrete pad or foundation.

In 1440, a shud was defined as a "... schudde, hovel, swyne kote or howse of sympyl hyllynge [covering] to kepe yn beestys".

Bike sheds range from little more than a supported roof to more complex structures with walls and locking doors or gates.

Snow sheds are strongly built timber or reinforced-concrete tunnels that protect railroad tracks (or roads) from avalanches.

In addition, sheds can be used to store items that are not suitable for indoor storage, such as petrol (gasoline), pesticides, or herbicides.

A pent shed features a single roof section that is angled downwards to let rainwater run off, with more headroom at the front than the back.

The main advantage of the reverse apex design is that the door opens into the widest part of the shed instead of the narrowest, so it is easier to reach into all areas to retrieve or store equipment.

Larger sheds provide more space for engaging in hobbies such as gardening, small engine repair, or tinkering.

In some cases, remote workers who live in mild climates use small to medium-sized wooden garden sheds as outdoor offices.

A number of decorative options can be added to sheds, such as dormers, shutters, flower boxes, finials, and weathervanes.

As well, practical options can be added such as benches, ramps, ventilation systems (e.g., in cases where a swimming pool heater is installed in a shed), and electric lighting.

For example, while metal sheds are fire and termite-resistant, they can rust over time, or be severely damaged by high winds or heavy snow loads.

Vinyl-sided, wood-framed sheds blend the strength of a wood frame with the maintenance-free aspect of vinyl siding (it does not need to be painted or varnished).

Metal sheds are a good choice when long-term strength and resistance to fire, rot, or termites are desired.

PVC resins and high-impact, UV light-resistant polyethylene make plastic outdoor sheds stronger, lighter, more durable, and more resistant to denting and chipping than wood, and tend to be more stable.

Many plastic sheds are modular to allow for easy extensions, peg-boards, shelving, attic-storage, windows, skylights, and other accessories to be added later if these additions are purchased from the manufacturer.

This includes keeping plant matter and debris from piling up beside the walls and on the roof, and occasional rot-proofing with preservatives.

If a coloured preservative oil or stain is used, a wooden shed can either be made to stand out as a feature within a garden, or to blend in with its surroundings.

Legislation such as the European Biocidal Products Regulation has reduced the number of effective active ingredients available for wood preservative formulations.

This is a quick and simple process that keeps costs down and encourages manufacturers to produce a wide variety, making dip-treated sheds the most popular and affordable type on the market.

[12] Pressure-treated sheds are made from timber planks that have had the moisture sucked out of them under vacuum conditions in a special cylinder.

A powerful preservative is then forced into the wood at high pressure until it is absorbed deep into the grain, becoming an integral part of the timber.

Although pressure-treated sheds tend to be more expensive than dip-treated ones, their big advantage is that they will not need any further preservative treatment during the guarantee period, saving owners time and money.

[13] One advantage of using wood sheds over metal versions is that it is easier to modify them by adding windows, doors, shelving, or exterior trim (etc.)

They offer good value for money because they hold up in all weather, including winters with heavy snowfall, as they use a strong wooden frame and the OSB panels have stronger structural support than thin metal or PVC siding or roofs.

Metal, plastic and resin sheds are cheaper, but they cannot handle the weight of snow in winter (roofs may cave in).

In the early and middle years of the 20th century, many garden sheds and domestic garages were made of asbestos-cement sheets supported on a very light angle-iron frame.

[14] In Australia and New Zealand the term shed can be used to refer to any building that is not a residence and which may be open at the ends or sides, or both.

[19] In contrast, in the novel Cold Comfort Farm by Stella Gibbons, Aunt Ada Doom saw "something nasty in the woodshed" and retreated to her bed for half a century.