Submarine hull

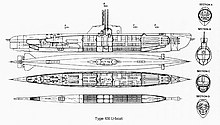

[1][2] However, when military submarines entered service in the early 1900s, the limitations of their propulsion systems forced them to operate on the surface most of the time; their hull designs were a compromise, with the outer hulls resembling a ship, allowing for good surface navigation, and a relatively streamlined superstructure to minimize drag under water.

Because of the low submerged speeds of these submarines, usually well below 10 knots (19 km/h), the increased drag for underwater travel by the conventional ship-like outer hull was considered acceptable.

[citation needed] Only late in World War II, when technology enhancements allowed faster and longer submerged operations and increased surveillance by enemy aircraft forced submarines to spend most of their times below the surface, did hull designs become teardrop shaped again, to reduce drag and noise.

It defines the hydrodynamic performance of submarine, which affects the amount of power required to drive the vessel through the water.

This term is especially appropriate for Russian submarine construction, where the light hull is usually made of thin steel plate, as it has the same pressure on both sides.

The pressure hull is generally constructed of thick high-strength steel with a complex stiffening structure and high strength reserve, and is divided by watertight bulkheads into several compartments.

The interhull space is used for some of the equipment which can tolerate the high external pressure at maximum depth and exposure to the water.

Even a one-inch (25 mm) deviation from cross-sectional roundness results in over 30 percent decrease of hydrostatic load capacity.

This also greatly increases their survivability – even if one pressure hull is breached, the crew members in the others are relatively safe if the submarine can be prevented from sinking, and there is less potential for flooding.

This is affordable for civilian research submersibles, but not military submarines, so their dive depth was always bounded by current technology.

World War One submarines had their hulls built of carbon steel, and usually had test depths of no more than 100 metres (330 ft).