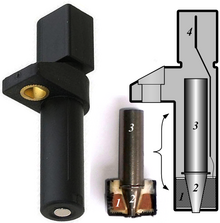

Crankshaft position sensor

A crank sensor (CKP)[1][2][3] is an electronic device used in an internal combustion engine, both petrol and diesel, to monitor the position or rotational speed of the crankshaft.

Before electronic crank sensors were available, the distributor would have to be manually adjusted to a timing mark on petrol engines.

This method is also used to "synchronise" a four stroke engine upon starting, allowing the management system to know when to inject the fuel.

Common mounting locations include the main crank pulley, the flywheel, the camshaft or on the crankshaft itself.

Some engines, such as GM's Premium V family, use crank position sensors which read a reluctor ring integral to the harmonic balancer.

If the engine is revved up with a bad or faulty sensor, it may cause misfiring, motor vibration or backfires.

Another type of crank sensor is used on bicycles to monitor the position of the crankset, usually for the cadence readout of a cyclocomputer.