Textile recycling

Results from academic studies demonstrate that textile reuse and recycling are more advantageous than incineration and landfilling.

The EPA reported that in 2018 alone, 17 million tons of textile municipal solid waste (MSW) was generated.

[8] By textile recycling, it decreases landfill space, creates less pollution, and reduces the consumption of power and water.

[2] These products are repurposed for other industries i.e. furniture, mattress, coarse yarn, home building, automotive, paper, and apparel.

[2] The remaining post-consumer waste can be directed towards second-hand retailers to be resold or passed on to warehouses dedicated to textile recycling.

[2] Despite being the smallest category, diamonds generate the largest amount of profit per item for recycling companies.

[2] Clothing and accessories that are considered diamonds include couture, Harley Davidson, Levi's, Ralph Lauren, and luxury fibers (for example cashmere).

[2] These second-hand clothing articles are in high demand and can be sold online, in retail boutiques, or in vintage shops.

[10] The energy values of burning MSW have been comparable with oil in terms of calories; however, there are obstacles to this process.

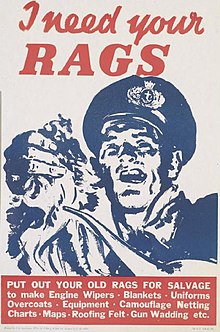

[2] Wiping and polishing cloths can be made from a combination of oleophilic and hydrophilic fibers which are often useful in industrial application.

[2] Shoddy involves creating new yarn products from the old materials, and is one of the most historical examples of textile recycling.

This wool is exported to European countries, whose cooler climates and flammability regulations result in a greater need for mungo.

According to Green America recycled textiles are sorted by color with zippers and buttons being removed using magnets and are then spun into yards of thread using weaving.

[4] Reuse occurs when textile owners rent, trade, swap, borrow, inherit products through second-hand stores, garage sales, online/flea markets, or charities.

[5] The number of times a material can be recycled is dependent on the quality of the fibers, which decreases with each cycle of mechanical processing.

[14] The major small scale production sites are from Eco Circle, Worn Again, Evrnu, and Ioncell.

[14] For PET, the starting materials are first broken down to the molecular level by using chemicals that facilitate glycolysis, methanolysis, hydrolysis, and/or ammonolysis.

[17] One specific region that is more progressive in applications of recycled textiles is Scandinavia, which has created mainstream market products.

[17] In Sweden, companies such as Lindex and H&M are including pre-consumer and post-consumer waste fibers within their new clothing lines.

[18] Inditex and Bill Gates’ Breakthrough Energy Ventures invested in the start-up recycling company Circ in July 2022, which has patented new technologies to reengineer used fibers.

[20] Goldman Sachs led an investment in mechanically recycled cotton company Recover Textile Systems in June 2022.

[21] Many luxury fashion brands are publicly displaying their investment in sustainability approaches, with a common goal to shift towards circular systems and utilizing re-engineered and/or biodegradable materials in their collections.