Timber roof truss

But such roofs were structurally weak, and lacking any longitudinal support, they were prone to racking, a collapse resulting from horizontal movement.

The king post is normally under tension, and requires quite sophisticated joints with the tie beam and principal rafters.

The opposite being a "Stehender Stuhl", which is the common roof truss type where simple vertical posts replace the more elaborate support structure in the image (highlighted in blue).

Lacking a tie beam,[11] the arch-braced (arched brace)[12] truss gives a more open look to the interior of the roof.

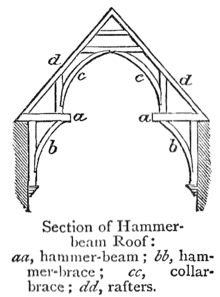

[13]The hammerbeam roof was the culmination of the development of the arch-braced truss, allowing greater spaces to be spanned.

The hammerbeam roof of Westminster Hall in London, designed by Hugh Herland and installed between 1395 and 1399, was the largest timber-roofed space in medieval Europe, spanning a distance of just over 20 metres (66 ft).

[21] Pre-fabricated wood trusses offer advantages in building construction through machine-made accuracy and tend to use less timber.

[23] The earliest wooden truss connections consisted of mortise-and-tenon joints and were most likely crafted at the construction site with the posts.

Since most early trusses were made from unseasoned posts, the subsequent shrinkage would create cracking at the mortise-and-tenon joints.

Additionally, the mortise-and-tenon joints in older trusses were located at the weakest point in the post, accelerating failure.

This is why holes were drilled slightly off-centre, allowing the peg to naturally pull the posts together with gravity.

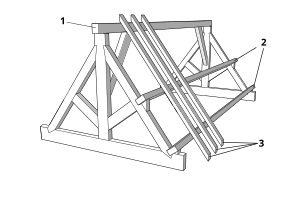

Key: 1: ridge beam, 2: purlins , 3: common rafters. This is an example of a "double roof" with principal rafters and common rafters.

Key: 1: king post, 2: tie beam, 3: principal rafters, 4: struts.

Key: 1: queen posts, 2: tie beam, 3: straining beam, 4: principal rafters.

Key: 1: principal rafters, 2: collar beam, 3: arch braces.