Saw

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge.

The kerf created by a given blade can be changed by adjusting the set of its teeth with a tool called a saw tooth setter.

The cut is made by placing the toothed edge against the material and moving it back and forth, or continuously forward.

In most modern serrated saws, the teeth are set, so that the kerf (the width of the cut) will be wider than the blade itself.

For example, a ripsaw has a tooth set that is similar to the angle used on a chisel, so that it rips or tears the material apart.

In archeological reality, saws date back to prehistory and most probably evolved from Neolithic stone or bone tools.

[9] By the end of the 17th century European manufacture centred on Germany, (the Bergisches Land) in London, and the Midlands of England.

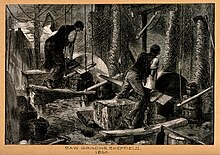

[10] In the mid 18th century a superior form of completely melted steel ("crucible cast") began to be made in Sheffield, England, and this rapidly became the preferred material, due to its hardness, ductility, springiness and ability to take a fine polish.

Early European saws were made from a heated sheet of iron or steel, produced by flattening by several men simultaneously hammering on an anvil.

[15] The use of steel added the need to harden and temper the saw plate, to grind it flat, to smith it by hand hammering and ensure the springiness and resistance to bending deformity, and finally to polish it.

[16] Most hand saws are today entirely made without human intervention, with the steel plate supplied ready rolled to thickness and tensioned before being cut to shape by laser.

A large measure of hand finishing remains to this day for quality saws by the very few specialist makers reproducing the 19th century designs.

In parts of early colonial North America, it was one of the principal tools used in shipyards and other industries where water-powered sawmills were not available.

It was so-named because it was typically operated over a saw pit, either at ground level or on trestles across which logs that were to be cut into boards.

Hand saws typically have a relatively thick blade to make them stiff enough to cut through material.

Some examples are: A class of saws for cutting all types of material; they may be small or large and the frame may be wood or metal.