Dry sump

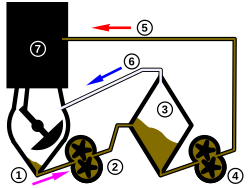

A dry-sump system is a method to manage the lubricating motor oil in four-stroke and large two-stroke piston driven internal combustion engines.

Dry sump systems may not be suitable for all applications due to increased cost, complexity, and/or bulk, among other factors.

In the wet-sump system of nearly all production automobile engines, the oil that's not actively circulating is stored in the sump, which is large enough for this purpose.

[1][2] An equilibrium pressure will be reached when the rate of gases entering the crankcase (blow-by gases past the piston rings, but also air leaks and oil vapor) equals the rate of gas removal from the scavenge pump capacity beyond what's required to remove just the oil.

They are also commonly used in racing cars and aerobatic aircraft, due to problems with g-forces, reliable oil supply, power output and vehicle handling.

The Chevrolet Corvette Z06 has a dry sump engine which requires an initial oil change after 500 miles.