Extraction of petroleum

Reservoirs of petroleum are formed through the mixture of plants, algae, and sediments in shallow seas under high pressure.

[1] Geologists and geophysicists use seismic surveys to search for geological structures that may form oil reservoirs.

A steel pipe (casing) is placed in the hole, to provide structural integrity to the newly drilled well bore.

The drilling process comes under "upstream", one of the three main services in the oil industry, along with mid-stream and downstream.

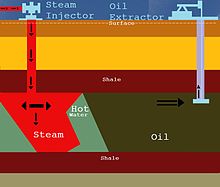

After natural reservoir drive diminishes and there is insufficient underground pressure to force the oil to the surface, secondary recovery methods are applied.

The typical recovery factor from water injection operations is about 30%, depending on the properties of the oil and the characteristics of the reservoir rock.

This type of cogeneration plant uses a gas turbine to generate electricity, and the waste heat is used to produce steam, which is then injected into the reservoir.

When prices are high, previously unprofitable wells are brought back into use, and when they are low, extraction is curtailed.

In some states such as Texas, there are tax incentives for using these microbes in what is called a secondary tertiary recovery.

Shale gas EUR is difficult to predict, and it is possible to choose recovery methods that tend to underestimate decline of the well beyond that which is reasonable.

Two-thirds of all worker fatalities were attributed to transportation incidents and contact with objects or equipment.

[10] Carbon emissions cause climate change which negatively impacts people's safety by raising sea levels and worsening weather.