Biogas

[2][3] The gas composition is primarily methane (CH4) and carbon dioxide (CO2) and may have small amounts of hydrogen sulfide (H2S), moisture and siloxanes.

[4] After removal of carbon dioxide and hydrogen sulfide it can be compressed in the same way as natural gas and used to power motor vehicles.

[7] Manufacturing of biogas from intentionally planted maize has been described as being unsustainable and harmful due to very concentrated, intense and soil eroding character of these plantations.

[13] Landfill gas is produced by wet organic waste decomposing under anaerobic conditions in a similar way to biogas.

Such white mineral deposits accumulate to a surface thickness of several millimeters and must be removed by chemical or mechanical means.

[28] Furthermore, by converting cattle manure into methane biogas instead of letting it decompose, global warming gases could be reduced by 99 million metric tons or 4%.

[33] In addition to these, the use of membrane separation technology for biogas upgrading is increasing, and there are already several plants operating in Europe and USA.

In 1974, a British documentary film titled Sweet as a Nut detailed the biogas production process from pig manure and showed how it fueled a custom-adapted combustion engine.

Biogas environments include wastewater digesters, landfills, and animal feeding operations (covered livestock lagoons).

This impact can be reduced by using correct combination of feedstocks, covered storage for digesters and improved techniques for retrieving escaped material.

[45] Projects such as NANOCLEAN are nowadays developing new ways to produce biogas more efficiently, using iron oxide nanoparticles in the processes of organic waste treatment.

Countries such as the United Kingdom and Germany now have legislation in force that provides farmers with long-term revenue and energy security.

The United States Clean Air Act and Title 40 of the Code of Federal Regulations (CFR) requires landfill owners to estimate the quantity of non-methane organic compounds (NMOCs) emitted.

According to a 2008 study, collected by the Science and Children magazine, methane biogas from cow manure would be sufficient to produce 100 billion kilowatt hours enough to power millions of homes across America.

However, California state officials have taken the position that biogas is "better used in hard-to-electrify sectors of the economy-- like aviation, heavy industry and long-haul trucking".

While countries such as Germany, Austria, Sweden and Italy are fairly advanced in their use of biogas, there is a vast potential for this renewable energy source in the rest of the continent, especially in Eastern Europe.

EBA's strategy defines three priorities: establish biogas as an important part of Europe's energy mix, promote source separation of household waste to increase the gas potential, and support the production of biomethane as vehicle fuel.

[76] Biogas in Germany is primarily extracted by the co-fermentation of energy crops (called 'NawaRo', an abbreviation of nachwachsende Rohstoffe, German for renewable resources) mixed with manure.

Moreover, new industries and markets were created in predominately rural regions entailing different new players with an economic, political and civil background.

Finally biogas will furthermore play an important role in the German renewable energy supply if good governance is focused.

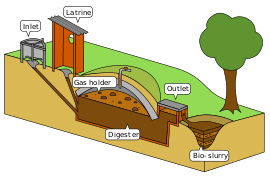

[82] Depending on size and location, a typical brick made fixed dome biogas plant can be installed at the yard of a rural household with the investment between US$300 to $500 in Asian countries and up to $1400 in the African context.

[83] A high quality biogas plant needs minimum maintenance costs and can produce gas for at least 15–20 years without major problems and re-investments.

In Asia, SNV is working in Nepal,[89] Vietnam,[90][91] Bangladesh,[92] Bhutan, Cambodia,[92] Lao PDR,[93] Pakistan[94] and Indonesia,[95] and in Africa; Rwanda,[96] Senegal, Burkina Faso, Ethiopia,[97] Tanzania,[98] Uganda, Kenya,[99] Benin and Cameroon.

Biogas which is mainly methane/natural gas can also be used for generating protein rich cattle, poultry and fish feed in villages economically by cultivating Methylococcus capsulatus bacteria culture with tiny land and water foot print.

This has led to the development of prefabricated digester for modular deployments as compared to RCC and cement structures which take a longer duration to construct.

In India, Nepal, Pakistan and Bangladesh biogas produced from the anaerobic digestion of manure in small-scale digestion facilities is called gobar gas; it is estimated that such facilities exist in over 2 million households in India, 50,000 in Bangladesh and thousands in Pakistan, particularly North Punjab, due to the thriving population of livestock.

Owing to simplicity in implementation and use of cheap raw materials in villages, it is one of the most environmentally sound energy sources for rural needs.

This is caused by the lack of heat control technology for digesters thus the co-digestion of different feedstock failed to complete in the cold environment.

[121]In the 1985 Australian film Mad Max Beyond Thunderdome the post-apocalyptic settlement Barter town is powered by a central biogas system based upon a piggery.

[citation needed] Contemporary biogas production provides new opportunities for skilled employment, drawing on the development of new technologies.