Flathead engine

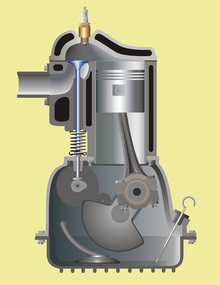

[5] The sidevalves are typically adjacent, sited on one side of the cylinder(s), though some flatheads employ the less common "crossflow" "T-head" variant.

[6] "Pop-up pistons" may be used with compatible heads to increase compression ratio and improve the combustion chamber's shape to prevent knocking.

The absence of a complicated valvetrain allows a compact engine that is cheap to manufacture, since the cylinder head may be little more than a simple metal casting.

[citation needed] At top dead centre, the piston gets very close to the flat portion of the cylinder head above, and the resultant squish turbulence produces excellent fuel/air mixing.

A feature of the sidevalve design (particularly beneficial for an aero-engine) is that if a valve should seize in its guide and remain partially open, the piston would not be damaged, and the engine would continue operating safely on its other cylinders.

[14][15][16][17] An advance in flathead technology resulted from experimentation in the 1920s by Sir Harry Ricardo, who improved their efficiency after studying the gas-flow characteristics of sidevalve engines.

[11] Sidevalve designs are still common for many small single-cylinder or twin-cylinder engines, such as lawnmowers, rotavators, two-wheel tractors and other basic farm machinery.

[1][20] The simplicity, lightness, compactness and reliability might seem ideal for an aero-engine, but because of their low efficiency, early flathead engines were deemed unsuitable.

[22][23] Flathead designs have been used on a number of early pre-war motorcycles, in particular US V-twins such as Harley-Davidson and Indian, some British singles, BMW flat twins and Russian copies thereof.