Silicone rubber keypad

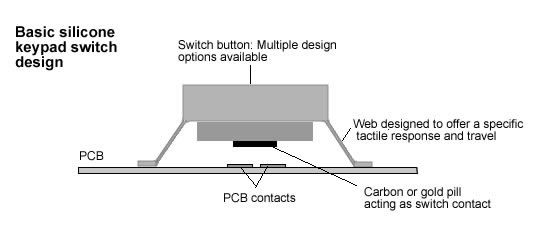

[1] The technology uses the compression molding properties of silicone rubber to create angled webbing around a switch center.

It is possible to vary the tactile response and travel of a key by changing the webbing design and/or the shore hardness of the silicone base material.

The recommended snap ratio for designers to maintain is 40%-60%; if dropped below 40% the keys will lose tactile feel but have an increased life.

Loss of tactile feel means the user will not receive a ‘click’ feedback during actuation.

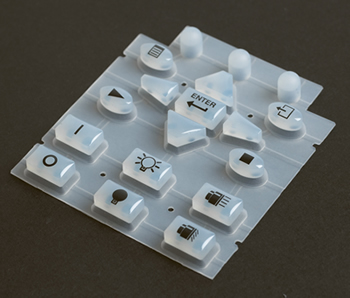

Individual legends can be printed on to a key allowing full customization of the keypad for its application.

This allows individual key to be illuminated using SMT LEDs placed on the printed circuit board.

[citation needed] Their involvement has led to advances in technology including the use of hard plastic key tops bonded to a rubber keypad and also the use of embossed Mylar layer to produce an enhanced tactile response.