Skiving (metalworking)

Skiving or scarfing is the process of cutting material off in slices, usually metal, but also leather or laminates.

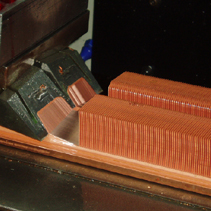

In metalworking, skiving can be used to remove a thin dimension of material or to create thin slices in an existing material, such as heat sinks where a large amount of surface area is required relative to the volume of the piece of metal.

This allows mutual initial positioning differences up to approximately 12 mm (0.47 in) followed by resilient automatic engagement.

Products using the process indirectly are tubes and pipes where the edge of the strip is accurately beveled prior to being folded into tubular form and seam welded.

The fins may be made much thinner and closer together than by extrusion or formed sheet processes, which can offer greater heat transfer in high-performance waterblocks for water cooling.