Solar desalination

[3] Two years later in Las Salinas, Chile, Swedish engineer Charles Wilson began building a solar distillation plant to supply freshwater to workers at a saltpeter and silver mine.

[4] In Italy, an open source design called "the Eliodomestico" by Gabriele Diamanti was developed for personal costing $50.

[8] Because of inexpensive methods of freshwater delivery and abundant low-cost energy resources, solar distillation has been viewed as cost-prohibitive and impractical.

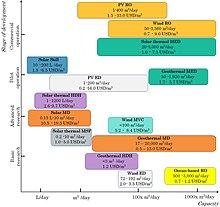

[2] Because of this proportionality and the relatively high cost of property and material for construction, distillation tends to favor plants with production capacities less than 200 m3/d (53,000 US gal/d).

The vapor condenses on the inner face of a sloping transparent cover, leaving behind salts, inorganic and organic components and microbes.

This requires less water to be heated and is easier to change the angle towards the sun which saves time and achieves higher temperatures.

[12] A diffusion still is composed of a hot storage tank coupled to a solar collector and the distillation unit.

[21][23] Fresh water can be extracted through four MD methods: Direct Contact (DCMD), Air Gap (AGMD), Sweeping Gas (SGMD) and Vacuum (VMD).

[25] Phase-change (or multi-phase) solar desalination[17][22][26] includes multi-stage flash, multi-effect distillation (MED), and thermal vapor compression (VC).

[17] It is accomplished by using phase change materials (PCMs) to maximize latent heat storage and high temperatures.

[17][26] Multi-stage flash (MSF) requires seawater to travel through a series of vacuumed reactors held at successively lower pressures.

[22] MED desalination requires less energy than MSF due to higher efficiency in thermodynamic transfer rates.

[28] In the MSF desalination process, seawater is heated and subjected to a series of flashings or rapid depressurizations in multiple stages.

In Kuwait a MSF facility uses parabolic trough collectors to provide solar thermal energy to produce 100 m3 of fresh water a day.

[8] And in Northern China an experimental, automatic, unmanned operation uses 80 m2 of vacuum tube solar collectors coupled with a 1 kW wind turbine (to drive several small pumps) to produce 0.8 m3/day.

Achieving highest efficiency requires controlled pressure drops across each stage and steady energy input.

As thermal energy storage capacity increases a more continuous process can be achieved and production rates approach maximum efficiency.

[31] Although it has only been used on demonstration projects, this indirect method based on crystallization of the saline water has the advantage of the low energy required.

There are some recent examples of this solar powered processes: the unit constructed in Saudi Arabia by Chicago Bridge and Iron Inc. in the late 1980s, which was shut down for its inefficiency.

[1] Second, the heat of condensation is valuable because it takes large amounts of solar energy to evaporate water and generate saturated, vapor-laden hot air.

Single phase desalination is predominantly accomplished with photovoltaics that produce electricity to drive RO pumps.

[38] Alternative methods that use solar thermal collection to provide mechanical energy to drive RO are in development.

[39] Economic and reliability considerations are the main challenges to improving PV powered RO desalination systems.

The intermittent nature of sunlight and its variable intensity throughout the day complicates PV efficiency prediction and limits night-time desalination.

Similarly, thermal energy storage systems ensure constant performance after sunset and on cloudy days.

Although this is a well-known process electrodialysis is not commercially suited for seawater desalination, because it can be used only for brackish water (TDS < 1000 ppm).

[38] Due to the complexity for modeling ion transport phenomena in the channels, performance could be affected, considering the non-ideal behavior presented by the exchange membranes.

[45] The basic ED process could be modified and turned into RED, in which the polarity of the electrodes changes periodically, reversing the flow through the membranes.

One example is in Japan, on Oshima Island (Nagasaki), which has operated since 1986 with 390 PV panels producing 10 m3/day with dissolved solids (TDS) about 400 ppm.