Solar thermal collector

Piping can be laser or ultrasound welded to the absorber sheet to reduce damage to the selective coating, which is typically applied prior to joining to large coils in a roll-to-roll process.

Absorber piping configurations include: A flat plate collector making use of a honeycomb structure to reduce heat loss also at the glass side too has also been made available commercially.

The vacuum that surrounds the absorber greatly reduces convection and conduction heat loss, therefore achieving greater energy conversion efficiency.

[citation needed] The manifold is wrapped in insulation (glass wool) and covered by a protective metal or plastic case also used for fixing to supports.

A Barium flash getter pump is commonly evaporated inside the high vacuum gap in between tubes to keep the internal pressure stable through time.

The high temperatures that can occur inside evacuated tubes may require special design to prevent thermal shock and overheating.

However, evacuated tube technology (especially for newer variants with glass-metal seals and heat pipes) still needs to demonstrate competitive lifetimes.

[14] However, evacuated tube collectors are well-suited to cold ambient temperatures and work well in situations of low solar irradiance, providing heat more consistently throughout the year.

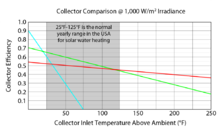

Unglazed collectors may be suitable in tropical or subtropical environments if domestic hot water needs to be heated by less than 20 °C (36 °F) over ambient temperature.

They offer the highest energy conversion efficiency of any non-concentrating solar thermal collector,[15] but require sophisticated technology for manufacturing.

Different from evacuated tube collectors, they make use of non-evaporable getter (NEG) pumps to keep the internal pressure stable through time.

A heat exchange fluid protects against freeze damage down to a locally determined risk temperature that depends on the proportion of propylene glycol in the mixture.

The main reason for its development was to eliminate the cost of moving a large mirror to track the sun as with parabolic dish systems.

Proponents of the solar bowl design claim the reduction in overall power output compared with tracking parabolic mirrors is offset by lower system costs.

The solar bowl design resulted from a project of the Electrical Engineering Department of the Texas Technical University, headed by Edwin O'Hair, to develop a 5 MWe power plant.

[citation needed] In locations with average available solar energy, flat plate collectors are sized approximately 1.2 to 2.4 square decimeter per liter of one day's hot water use.

Many unglazed collectors are made of polypropylene and must be drained fully to avoid freeze damage when air temperatures drop below 44 °F (7 °C) on clear nights.

[24] A smaller but growing percentage of unglazed collectors are flexible meaning they can withstand water freezing solid inside their absorber.

Large-scale unglazed solar hot water heaters, like the one at the Minoru Aquatic Center in Richmond, BC operate at lower temperatures than evacuated tube or boxed and glazed collector systems.

Although they require larger, more expensive heat exchangers, all other components including vented storage tanks and uninsulated plastic PVC piping reduce the costs of this alternative dramatically compared to the higher temperature collector types.

Many applications are now being installed where the transpired collector preheats the fresh air entering a heat recovery ventilator to reduce the defrost time of HRV's.

Air heated through a solar collector and then passed over a medium to be dried can provide an efficient means by which to reduce the moisture content of the material.

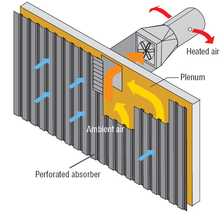

Collectors are commonly classified by their air-ducting methods as one of three types: Collectors can also be classified by their outer surface: Offering the highest efficiency of any solar technology the through-pass configuration, air ducted onto one side of the absorber passes through a perforated material and is heated from the conductive properties of the material and the convective properties of the moving air.

In back-pass, front-pass, and combination type configurations the air is directed on either the back, the front, or on both sides of the absorber to be heated from the return to the supply ducting headers.

In cold climates, air passing next to the glazing will additionally cause greater heat loss, resulting in lower overall performance of the collector.

Glazed systems usually have a transparent top sheet and insulated side and back panels to minimize heat loss to ambient air.

The technology has been extensively monitored by these government agencies, and Natural Resources Canada developed the feasibility tool RETScreen™ to model the energy savings from transpired solar collectors.

Since that time, several thousand transpired solar collector systems have been installed in a variety of commercial, industrial, institutional, agricultural, and process applications in countries around the world.

This technology was originally used primarily in industrial applications such as manufacturing and assembly plants where there were high ventilation requirements, stratified ceiling heat, and often negative pressure in the building.

High temperatures are suitable for electricity generation using conventional methods like steam turbine or a direct high-temperature chemical reaction such as liquid salt.