Styrene-butadiene

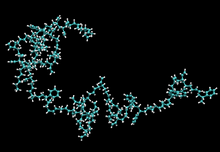

The styrene/butadiene ratio influences the properties of the polymer: with high styrene content, the rubbers are harder and less rubbery.

Reaction vessels are typically charged with the two monomers, a free radical generator, and a chain transfer agent such as an alkyl mercaptan.

By "capping" the growing organic radicals, mercaptans (e.g. dodecylthiol), control the molecular weight of the product.

For tire manufacture, S-SBR is increasingly favored because it offers improved wet grip and reduced rolling resistance, which translate to greater safety and better fuel economy, respectively.

[5] The material was initially marketed with the brand name Buna S. Its name derives Bu for butadiene and Na for sodium (natrium in several languages including Latin, German, and Dutch), and S for styrene.

In the latter application, it offers better durability, reduced shrinkage and increased flexibility, as well as being resistant to emulsification in damp conditions.

SBR aids the bond strength, reduces the potential for shrinkage and adds an element of flexibility.

SBR is also used as a binder in lithium-ion battery electrodes, in combination with carboxymethyl cellulose as a water-based alternative for, e.g. polyvinylidene fluoride.

It was originally developed prior to World War II in Germany by chemist Walter Bock in 1929.