Surface-mount technology

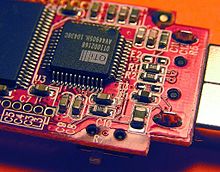

It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

[4] By the late 1990s, the great majority of high-tech electronic printed circuit assemblies were dominated by surface mount devices.

[5] Components were mechanically redesigned to have small metal tabs or end caps that could be directly soldered to the surface of the PCB.

Surface mounting lends itself well to a high degree of automation, reducing labor cost and greatly increasing production rates.

Conversely, SMT does not lend itself well to manual or low-automation fabrication, which is more economical and faster for one-off prototyping and small-scale production; this is one reason why many through-hole components are still manufactured.

They first enter a pre-heat zone, where the temperature of the board and all the components is gradually, uniformly raised to prevent thermal shock.

Another technology that is becoming popular again is special fluorocarbon liquids with high boiling points which use a method called vapor phase reflow.

Due to environmental concerns, this method was falling out of favor until lead-free legislation was introduced which requires tighter controls on soldering.

If the circuit board is double-sided then this printing, placement, reflow process may be repeated using either solder paste or glue to hold the components in place.

However, most electronic assemblies are made using a "No-Clean" process where the flux residues are designed to be left on the circuit board, since they are considered harmless.

However, it is generally suggested to wash the assembly, even when a "No-Clean" process is used, when the application uses very high frequency clock signals (in excess of 1 GHz).

[13] The main advantages of SMT over the through-hole technique are:[14][15] Defective surface-mount components can be repaired by using soldering irons (for some connections) or a non-contact rework system.

In most cases, a rework system is the better choice because SMD work with a soldering iron requires considerable skill and is not always feasible.

Reworking usually corrects some type of error, either human- or machine-generated, and includes the following steps: Sometimes hundreds or thousands of the same part need to be repaired.

However, a whole new level of rework arises when component failure is discovered too late, and perhaps unnoticed until the end user of the device being manufactured experiences it.