Thermal expansion valve

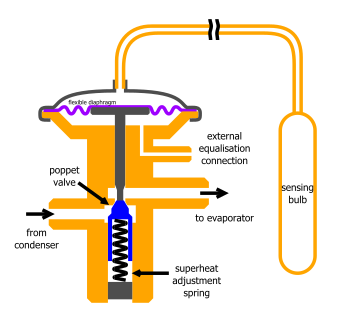

A TXV type expansion device has a sensing bulb that is filled with a liquid whose thermodynamic properties are similar to those of the refrigerant.

No superheat indicates that the refrigerant is not being fully vaporized within the evaporator and liquid may end up recirculated to the compressor which is inefficient and can cause damage.

On the other hand, excessive superheat indicates that there is insufficient refrigerant flowing through the evaporator coil, and thus a significant portion toward the end is not providing cooling.

Therefore, by regulating the superheat to a small value, typically only a few °C, the heat transfer of the evaporator will be near optimal, without excess liquid refrigerant being returned to the compressor.

Spring-type valves may be fixed, or adjustable, although other methods to ensure a superheat also exist, such as the sensing bulb having a different vapor composition to the rest of the system.

The cost, however, is determining a certain flow of refrigerant that will not reach the suction line in a fully evaporated state while the heat load is particularly low, and that the compressor must be designed to handle.

This feature helps to control the compressor's maximum operating torque to a value that is acceptable for the application, such as a small displacement car engine.

A low refrigerant charge condition is often accompanied when the compressor is operational by a loud whooshing sound heard from the thermal expansion valve and the evaporator, which is caused by the lack of a liquid head right before the valve's moving orifice, resulting in the orifice trying to meter a vapor or a vapor/liquid mixture instead of a liquid.

In this type, either a sensing bulb is located within the suction line connection within the valve body and is in constant contact with the refrigerant that flows out of the evaporator's outlet, or a heat transfer means is provided so that the refrigerant is able to exchange heat with the sensing charge contained in a chamber located above the diaphragm as it flows to the suction line.