Thermal-transfer printing

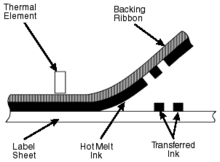

The heated element immediately melts the wax- or resin-based ink on the side of the ribbon film facing the substrate, and this process, in combination with the constant pressure being applied by the print-head locking mechanism immediately transfers it onto the substrate.

When a dot "turns off", that element of the print head immediately cools down, and that part of the ribbon thereby stops melting/printing.

If one were to hold a strip of used carbon ribbon up to the light, one would see an exact negative of the images that have been printed.

Thermal-printing technology can be used to produce color images by adhering a wax-based ink onto paper.

However, wax-resin compounds and full resins can be used on materials such as polypropylene or polyester in order to increase durability.

The paper then passes over the print drum, at which time the image is transferred, or transfixed, to the page.

This system is similar to water-based inkjets, provided that the ink has low viscosity at the jetting temperature 60 °C (140 °F).

Costs of upkeep and ink are comparable to color laser printers, while "standby" power usage can be very high, about 200 W. MicroDry is a computer printing system developed by the Alps Electric of Japan.

The main application of these printers is to produce barcode labels for product and shipping identification.