Torque tube

In contrast, the Hotchkiss drive transmits the traction forces to the car frame by using suspension components such as leaf springs or trailing arms.

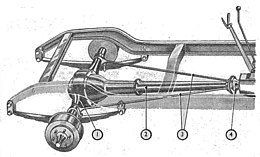

The combination of the panhard rod and the torque tube allows the easy implementation of soft coil springs in the rear to give good ride quality, as in Buicks after 1937.

However, because of the greater unsprung weight of the torque tube and radius rods, there may be a "little hopping around of the rear end when cornering fast or on washboard roads".

[12] The Nash 600 model adopted torque-tube drive in 1941 without an enclosed joint, but utilized a "horizontal yoke at the front end of the torque tube is supported by rubber biscuits at each side.

"[13] After the merger of Nash and Hudson in 1954, American Motors Corporation (AMC) continued to use the coil spring and torque tube rear suspension design on their large-sized cars (Rambler Classic and Ambassador) from the 1956 through the 1966 model year.

[16] The 1961 Pontiac Tempest was introduced as a new model, featuring an inline 4 coupled to a transaxle via a torque tube, giving it a perfect 50-50 front-rear weight balance.

[18] This design was unlike any other Chevrolet model "to isolate impacts to the rear wheels, cut down on road noise, and reduce engine vibration ... also allows a reduction in the height of the drive shaft and tunnel.

"[19] The continuing limited production of the Avanti switched to a new chassis in 1986 that utilized a torque tube along with an independent rear suspension.