Unified Thread Standard

It is the main standard for bolts, nuts, and a wide variety of other threaded fasteners used in these countries.

It has the same 60° profile as the ISO metric screw thread, but the characteristic dimensions of each UTS thread (outer diameter and pitch) were chosen as an inch fraction rather than a millimeter value.

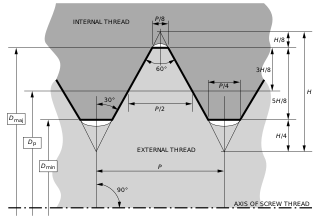

The outermost 1⁄8 and the innermost 1⁄4 of the height H of the V-shape are cut off from the profile.

The relationship between the height H and the pitch P is found using the following equation where θ is half the included angle of the thread, in this case 30°:[1]

In an external (male) thread (e.g., on a bolt), the major diameter Dmaj and the minor diameter Dmin define maximum dimensions of the thread.

This means that the external thread must end flat at Dmaj, but can be rounded out below the minor diameter Dmin.

Conversely, in an internal (female) thread (e.g., in a nut), the major and minor diameters are minimum dimensions, therefore the thread profile must end flat at Dmin but may be rounded out beyond Dmaj.

This number pair is optionally followed by the letters UNC, UNF or UNEF (Unified) if the diameter-pitch combination is from the coarse, fine, or extra fine series, and may also be followed by a tolerance class.

[4] The standard thread pitch is approximately 1/4 of the major diameter.

The thread form is slightly modified to increase the minor diameter, and thus the strength of screws and taps.

The major diameter still extends to within 1/8H of the theoretical sharp V, but the total depth of the thread is reduced 4% from 5/8H = 5/8 cos(30°) P ≈ 0.541P to 0.52P.

[5] This increases the amount of the theoretical sharp V which is cut off at the minor diameter by 10% from 0.25H to 7/8 − 0.52/cos 30° ≈ 0.27456H.

Standardization efforts in the late 19th and the early part of the 20th century reduced the range of sizes considerably.

Now, it is less common to see machine screws larger than #14, or odd number sizes other than #1, #3 and #5.

Currently this gauging for UTS is controlled by: These standards provide essential specifications and dimensions for the gauges used on Unified inch screw threads (UN, UNR, UNJ thread form) on externally and internally threaded products.

It also covers the specifications and dimensions for the thread gauges and measuring equipment.

It also establishes the criteria for screw thread acceptance when a gauging system is used.

A classification system exists for ease of manufacture and interchangeability of fabricated threaded items.

The letter suffix "A" or "B" denotes whether the threads are external or internal, respectively.

The pitch diameter is indicated as Dp in the figure shown above.