Unimog 406

There were eleven[5] different types made of the Unimog 406, which were available in four models (U 65 – U 84) with a closed two-door or four-door cab, as Cabrio and as an OEM part (a "half" Unimog lacking the rear part, as a basis for third party vehicle manufacturers).

[6] The initial Unimog concept was favoured by customers and accessory manufacturers, however, starting in the early 1960s, they desired a "heavy duty Unimog", following the trend of more powerful agricultural tractors beginning in the late 1950s which was due to German agriculture's shift to heavy mechanisation requiring less personnel.

Analysts warned that the demand for the Unimog 411 would pass the zenith after 1960 and fall below 3000 produced units per year.

Also, a decline of the military Unimog 404 production was foreseeable since the Bundeswehr had reached their required number of vehicles for the majority of their regiments and battalions.

The 406 was still supposed to be an agricultural and forestry vehicle and tractor but have a greater wheelbase, a higher top speed, the downbent frame of the Unimog 404[8] and a stronger engine.

Since Heinrich Rößler, the leader of the Unimog development did not want this engine, it was decided to use the, also direct injected, six-cylinder OM 352 instead.

[10] New tyres had to be developed by Dunlop and Continental, also, the Unimog 406 needed a new hydraulics system for auxiliary devices[11] and a new drivetrain with new axles and a new gearbox for the increased engine power.

Several new 1,000 Mp (9,807 kN) sheet panel presses had to be installed in the plant in Gaggenau for producing the closed cabs.

[13] The final presentation of the Unimog 406 was at the German Agricultural Society (DLG)-exhibition in Munich 1962, led by the Daimler-Benz board of directors.

[14] In the run-up to the presentation on 20 May 1962 a lot of minor Unimog changes and improvements as well as improvisations were made.

Yearly improvements increased the quality of the Unimog, the highest production figures were reached in the first half of the 1970s.

[22] 1967 brought only minor changes, the driver and passenger seats were upgraded, the rear-view mirror was modified.

[24] With the 1969 model changes, Daimler-Benz introduced the hinged windscreen for the Cabrio and a new closed cab with a bigger ventilation flap.

New safety regulations required a roll bar for the 406, also, the closed cab models were equipped with two additional rear windows.

It was fitted with bigger, rectangular indicators, new tail lights, upgraded portal axles and a new aluminium bed.

[29] The all-wheel-drive switching mechanism was upgraded to a pneumatic version in 1977, the chromed moldings on the front grille were removed in 1979.

The 406 was used as a basis for road-rail-vehicles made by external companies, the rated towing capacity is up to 300 t.[30] Initially, the Unimog 406 was offered with a 65 PS (48 kW) engine, this figure was later increased to 84 PS (62 kW) and series production models never exceeded it.

The first prototype of a road legal tractor for local hauling and internal works transport in the Unimog family was the 406.200 A in September 1969.

[18] The family included similar models all based on the technical and optical design of the Unimog 406 with different engines, wheelbases and applications.

Since Daimler-Benz also wanted to offer an inexpensive version of the long wheelbase model, they created the Unimog 413.

Unlike other Unimogs, it was sold under the Freightliner brand name and classified as Small Emplacement Excavator (SEE) tractor that was used as an engineer vehicle.

For powering mountable equipment, two standard switchable 540/1000 rpm PTOs are built in; both can be switched on and off independently.

Starting in 1970, the cabrio models were fitted with a roll bar that protects the driver in case of an accident.

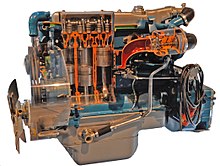

[40] Initially, the water-cooled straight-six precombustion chamber diesel engine type OM 312 powered the Unimog 406.

The ladder frame allows torsional flexing at the front and rear part but is rather rigid at its centre.

[41] The portal axles have reduction gears so that the Unimog would have a good ground clearance even with small wheels.

Since the torque tubes hold the portal axles in place, the Unimog does not need longitudinal control arms.

[44] The 406 has the fully synchronised four-speed UG-2/27 group sliding gearbox that is designed for a maximum input torque of 27 kp·m (264.8 N·m).

An additional air compressor was available that reduces the amount of time required to fill the compressed-air tanks.

Daimler-Benz never offered the standard and high-power output versions for the Unimog 406, since its gearbox and clutch are designed for an input torque of only 27 kp·m (264.8 N·m).

Front and rear part of the Unimog frame allow torsional flexing while the centre is rigid.