V6 engine

The first V6 engines were designed and produced independently by Marmon Motor Car Company, Deutz Gasmotoren Fabrik and Delahaye.

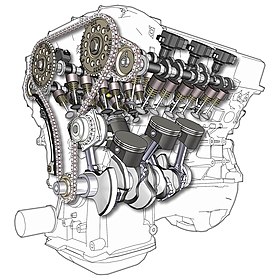

To reduce the vibrations caused by this imbalance, most V6 engines use a harmonic damper on the crankshaft and/or a counter-rotating balance shaft.

[4] When individual crank pins are used for each cylinder (i.e. using a six-throw crankshaft), an even firing interval of 120 degrees can be used.

The inline-three engine that forms each cylinder bank, however, produces unbalanced rotating and reciprocal forces.

These forces remain unbalanced in all V6 engines, often leading to the use of a balance shaft to reduce the vibration.

More recent designs often use a three-throw crankshaft with 'flying arms' between the crankpins to allow an even firing interval of 120 degrees to be achieved.

A pair of counterweights on the crankshaft can then be used to almost perfectly cancel out the primary forces[5]: 16 and reduce the secondary vibrations to acceptable levels.

[5]: 16 [7] Such a 'split' crankpin is weaker than a straight one, but modern metallurgical techniques can produce a crankshaft that is adequately strong.

A balance shaft and/or crankshaft counterweights can be used to reduce vibrations in 90 degree V6 engines.

[5]: 14–44 At first glance, 120 degrees might seem to be the optimal V-angle for a V6 engine, since pairs of pistons in alternate banks can share crank pins in a three-throw crankshaft and the combustion forces are balanced by the firing interval being equal to the angle between the cylinder banks.

However, the primary imbalance caused by odd number of cylinders in each bank still remains in a 120 degree V6 engine.

The V6 engine used a 60 degree V-angle and six crankpins, resulting in an evenly-spaced firing order to reduce vibrations.

Initially an uneven-firing engine, Buick later redesigned the crankshaft to a "split-pin" configuration to create an "even-firing" version.

After it became the 3800 V6 in 1990, the engine gained a reputation as a reliable, powerful, fuel-efficient workhorse that became a mainstay of GM's FWD mid-size and full-size cars.

Eventually, the first German V6 engine was a 2.8 liter 90° V6 that was launched in the 1990 Audi 100, and the narrow-angle VR6, which was introduced across Volkswagen's mid-size and sports car lineup in the 1990s.

The Lancia Aurelia (the first series production car with a V6 engine) was also successful in motor racing.

Four of the Aurelia B20 Coupes were entered in the 1951 Mille Miglia with the best placed cars finishing second and fourth.

The D24 competed in sports car racing and won the 1953 Carrera Panamericana with Juan Manuel Fangio at the wheel.

The Dino V6 underwent several evolutions, including a 2.4 L (146 cu in) version used in the 1958 Ferrari 246 Formula One racing car.

[17][18] A few years later, the 1961-1964 Ferrari 156 Formula One car used a new V6 engine with a V-angle of 120 degrees and a displacement of 1.5 L (92 cu in).

A notable racing use of the Alfa Romeo V6 engine was the Alfa Romeo 155 V6 TI, designed for the 1993 DTM season and equipped with a 2.5 L (150 cu in) engine making a peak power of 360 kW (490 PS) at 11,900 rpm.

A turbocharged 2.0 L (122 cu in) version was used in the Renault Alpine A442, which won the 24 Hours of Le Mans in 1978.

A turbocharged 1.5 L (92 cu in) version of the Renault-Gordini CH1 engine was introduced in the 1977 Renault RS01 Formula One car.

[citation needed] The first V6 engine to reach production was built from 1908 to 1913 by the Deutz Gasmotoren Fabrik in Germany.