Volkswagen Westmoreland Assembly

Built with the largest incentive package the Commonwealth of Pennsylvania had ever offered, the factory had an estimated annual capacity of 240,000 cars, and reached production of 200,000 in 1980.

[1] Initially the plant was successful, but numerous factors contributed to a sharp decline in sales of the cars manufactured at Westmoreland and the factory's ultimate demise.

Increased competition in the North American small car market, easing of the period's fuel crisis, poorly received changes to the character of the cars, VWoA's long product life-cycle, the internal economics of the plant, persistent labor unrest and poor networking between Westmoreland and Volkswagen headquarters in Germany.

Prior to development of Westmoreland Assembly, Volkswagen of America was headed by James W. (Jim) McLernon, a former Chevrolet manufacturing chief.

Toni Schmücker, VW management board Chairman, selected McLernon to investigate feasibility of US production,[1] in part to help the company avoid international currency fluctuations and high German wages.

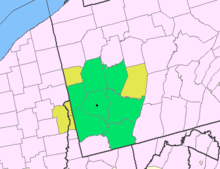

[12] After investigating five sites and narrowing the field to two alternate sites, a former Westinghouse appliance factory in Columbus, Ohio, and a federal tank plant in the Cleveland suburb of Brook Park,[2][13] VWoA signed a 30-year lease on Chrysler's unfinished New Stanton plant originally constructed in 1969[14] on 1,200 acres (5 km2)[4] at Route 119 in East Huntingdon Township – just outside New Stanton, Pennsylvania.

Richard S. Cummins, the plant manager, described the inside of the largest unfinished building with 2.1 million square feet, as a "three-dimensional chess-board covering an area of over 37 football fields.

[1] In the richest corporate deal to date in Pennsylvania history, state and local officials offered VWoA an incentive package worth nearly $100 million in government assistance, highway and rail improvements and a property-tax exemption.

[4] VW subsequently purchased an American Motors stamping plant in South Charleston, West Virginia, investing further to make the factory capable of producing exterior sheet metal stampings for Westmoreland[1] and then purchased a small plant in Fort Worth, Texas for manufacture of the air-conditioning and heating systems and plastic-trim to facilitate integration of factory installed air-conditioning in the Westmoreland-manufactured cars.

[17] Toni Schmücker, Richard E Dauch, James McLernon, U.S. Treasury Secretary Michael Blumenthal, Pennsylvania Governor Milton Shapp and 1,200 employees were on hand the day the first car came off of the line.

"[16] According to Richard Dauch, who was general manufacturing manager for Volkswagen Manufacturing of America from 1976 to 1978, "within 18 months, from 1976 until April 10, 1978, we had production, excellent quality with no product recalls, over 1,000 (completed cars) a day within two months of launch, two-door, four-door, diesel, K-Jetronic (fuel injection), 10 different body colors, four different interiors.

In his 2002 book Getting the Bugs Out: the Rise, Fall, and Comeback of Volkswagen in America, David Kiley said that "the German character was fading into oblivion.

[24] Consumers Union ranked the VWoA Westmoreland vehicles in 1977-79 had "worse than average maintenance record, including an oil burning problem.

[24] The plant was organized by the United Auto Workers; a 1992 New York Times article described it as the only "transplant" factory (a factory of a foreign automotive company in the US) that the UAW had succeeded in representing, and that the plant "began with a strike and lurched from problem to problem before closing"[29] From the outset, minorities picketed the site, seeking fair treatment in the hiring process[4] and by its first 20 months of operation, workers had staged six walkouts.

[30] On October 13, 1978, six months after the plant opened, UAW workers staged a wildcat strike at Westmoreland for salaries equal to those received by General Motors Corporation employees.

[26] Tim Moran, writing for Automotive News in 2005, said the styling of the main product became too old, the fuel crisis had eased, Wolfsburg was too slow to adapt to changing conditions and costs became too high.

[21] Commenting on the US plant closings in a 1998 Volkswagen publication about the history of Volkswagen Mexico, Dr. Carl Hahn who was Chairman of Volkswagen AG at the time said "The transfer of vehicle production to Mexico was done not only because of production losses in the U.S., but also with an eye to boosting sales in the US automotive market again through import to that country of low-cost vehicles made in Puebla... the decline of the US auto market had been foreseen for some time since the costs involved in US auto production were not competitive with European costs.

"[39] After its closing, VWoA sold the welding line,[40] tooling and other production equipment from Westmoreland Assembly to First Automotive Works of Changchun, China, producing the Volkswagen Jetta (A2) for over 30 years and contributing to the explosion of the Chinese auto market.

[citation needed] Automotive News reported in 2005, that the Corporation for Enterprise Development, a Washington economic think tank, estimated that "taxpayers were left with more than $70 million in incentives and loans used to lure (Westmoreland Assembly), whose promise never fully materialized.