Wetsuit

The insulation properties of neoprene foam depend mainly on bubbles of gas enclosed within the material, which reduce its ability to conduct heat.

[3] Wetsuits became available in the mid-1950s and evolved as the relatively fragile foamed neoprene was first backed, and later sandwiched, with thin sheets of tougher material such as nylon or later spandex (also known as lycra).

Activities include underwater diving, sailing, sea rescue operations, surfing, river rafting, whitewater kayaking and in some circumstances, endurance swimming.

However, at a depth of about 15 metres (50 ft) of water, the thickness of a typical neoprene foam will be halved and its conductivity will be increased by about 50%, allowing heat to be lost at three times the rate at the surface.

Softer, lighter, and more elastic grades contain a higher percentage of gas bubbles, and are comfortable and provide effective insulation at or near the surface where they retain much of their thickness.

Foamed neoprene is very buoyant, helping swimmers to stay afloat, and for this reason divers need to carry extra weight based on the volume of their suit to achieve neutral buoyancy near the surface.

Breath-hold divers do not have this option and have the handicap of reduced buoyancy at depth due to lung gas compression in addition to suit volume loss.

In this case, the water would quickly reach skin temperature and gas bubbles in the fabric would continue to act as the thermal insulation to keep it that way.

[17] However, it was Willard Bascom, an engineer at the Scripps Institution of Oceanography in La Jolla, California, who suggested foamed neoprene as a feasible material to Bradner.

[16] The United States Navy also turned down Bradner's and Bascom's offer to supply its swimmers and frogmen with the new wetsuits due to concerns that the gas in the neoprene component of the suits might make it easier for naval divers to be detected by underwater sonar.

[17] Jack O'Neill started using closed-cell neoprene foam which he claimed was shown to him by his bodysurfing friend, Harry Hind, who knew of it as an insulating material in his laboratory work.

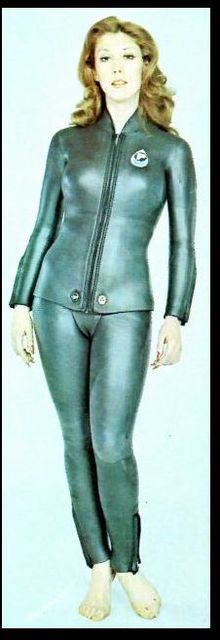

The Heinke Dolphin Suit[27] of the same period, also made in England, came in a green male and a white female version, both manufactured from natural rubber lined with stockinet.

As early as July 1951, underwater hunters in Australia were experimenting with a natural rubber wetsuit "of a 'wrap on' variety, which does not set out to be 100% waterproof (but it is claimed that) the leakage of water through it is so slow that body warmth under it is maintained for hours.

"[28] By May 1953, the Bondi underwater equipment manufacturer Undersee Products was already distributing this singlet-like design commercially to Australian sporting goods stores, where it was described thus: "Made from heavy sheet rubber, the Sealskin suit is most effective when worn over a football jersey.

[30] To mitigate this issue, divers resorted to generously applying talc powder to both the suit and their body to facilitate smoother sliding of the rubber material.

A small strip of neoprene reversed with the rubber against the skin could help provide a sealing surface to keep water out around the neck, wrists, and ankles.

In 1960, the British Dunlop Sports Company brought out its yellow Aquafort neoprene wetsuit, whose high visibility was intended to improve diver safety.

In a rubber wetsuit, this does not work well for a number of reasons, the main one being that punching holes straight through both layers of foam for the thread opens up passages for water to flow in and out of the suit.

To prevent needle holes from leaking, O'Neill fabricators developed a seam-tape which combined a thin nylon layer with a polyester hemming tape.

Armstrong, was one of the first designs combining a turtle-neck based on the popular Sealsuit[clarification needed] with a flexible lightweight YKK horizontal zipper across the back shoulders similar in concept to the inflatable watertight Supersuit (developed by Jack O'Neill in the late 1960s).

[citation needed] Some triathlon wetsuits go further, and use rubber-molding and texturing methods to roughen up the surface of the suit on the forearms, to increase drag and help pull the swimmer forwards through the water.

Extremely thin 1 mm neoprene is also often used in the under-arm area, to decrease stretch resistance and reduce strain on the swimmer when they extend their arms out over their head.

[citation needed] The cut surfaces are usually bonded to a synthetic knit fabric, which provides much greater tear resistance, at the expense of some loss of flexibility and stretch.

This fabric can be bonded to one or both surfaces in various combinations of composition, weave, weight and colour, and can be thin and relatively smooth and fragile, thicker and stronger and less stretchy,for high wear areas, or a plush type liner to reduce water flow.

[42] Both smoothskin and fabric lined surfaces can be printed to produce colour patterns such as camouflage designs, which may give spearfishermen and combat divers an advantage.

[44] Usually a wetsuit has no covering for the feet, hands or head, and the diver must wear separate neoprene boots, gloves and hood for additional insulation and environmental protection.

Other accessories to the basic suit include pockets for holding small items and equipment, and knee-pads, to protect the knee area from abrasion and tearing, usually used by working divers.

In many water sports such as scuba diving, surfing, kayaking, windsurfing, sailing and even fishing, bootees may be worn to keep the feet warm in the same way that a wetsuit would.

Where boots are worn with a wetsuit they are usually tucked under the leg of the suit for streamlining, to help hold the zip closed, and to keep foreign objects out.

For surfing, windsurfing, kitesurfing and similar sports, bootees are typically worn where the weather is so cold that the surfer would lose some degree of functionality in the feet.