William Beardmore and Company

William Beardmore and Company was a British engineering and shipbuilding conglomerate based in Glasgow and the surrounding Clydeside area.

It was established by Reoch Brothers & Co in 1837 and was later acquired by Robert Napier in 1841 to make forgings and iron plates for his new shipyard in Govan.

By 1896 the works covered an area of 25 acres (10 ha) and was the largest steelworks in Scotland, specialising in the manufacture of steel forgings for the shipbuilding industry of the River Clyde.

In 1900, Beardmore took over the shipyard of Robert Napier and Sons in Govan,[1] a logical diversification from the company's core steel forgings business.

[1] However this acquisition and construction overstretched company's limited financial resources and after being refused additional borrowings it had to raise new funds otherwise.

[3] Armstrong Whitworth also considered investing but decided against it due to high debt load of the company.

This work was facilitated by the construction of the Arrol Gantry, a large steel framework supporting nine high-speed electric cranes.

Beardmore expanded the activities at Dalmuir to include the manufacture of all sorts or arms and armaments, the site employing 13,000 people at its peak.

Several American railroads had self-propelled cars fitted with Westinghouse engines derived from Beardmore designs.

Beardmore also built 50 of the Nieuport 12 under licence, incorporating many of their own refinements however production was delayed sufficiently that by the time they entered service the aircraft were obsolete and were primarily relegated to training duties or placed into storage and never used.

It had the first aircraft built for it by the Rohrbach Metal Aeroplane Company in Copenhagen, building the second itself and they were delivered to the RAF as the Beardmore Inverness.

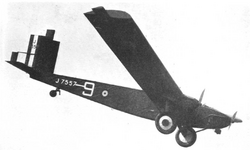

In addition, a large, experimental, all-metal trimotor transport aircraft was designed and built at Dalmuir and delivered to the Royal Air Force as the Beardmore Inflexible.

Beardmore produced a line of aircraft engines, including the Cyclone, Meteor, Simoon, Tornado (used in the R101 airship), Typhoon and Whirlwind.

In 1917, Beardmore bought Sentinel Waggon Works, a manufacturer of steam-powered railway locomotives, railcars and road vehicles.

In 1919 a range of cars was announced, to be made by a subsidiary company, Beardmore Motors Ltd, based in factories in Glasgow and the surrounding area; Anniesland, Coatbridge and Paisley.

[30] A highly modified version of the Super Sports, with a 2-litre engine broke the course record at the Shelsley Walsh hill climb in 1924.

The model they introduced, in 1954 was the Mk7 Paramount, which had a traditional style coachbuilt body, of aluminium panels over an ash frame, built by Windover.

In 1966, when Metropolitan-Cammell bought Weymann, taxi production was moved to MCW's factory at Washwood Heath, Birmingham, where it ended in late 1966.

During the 1970s the site was converted into the Clydebank Industrial Estate and in recent years has also formed the location of the Golden Jubilee Hospital and the Beardmore Hotel.

[36] It was at Parkhead Forge that James spotted young engineering manager Ian MacGregor who scabbed during a strike by driving a crane himself for two weeks.