Yule Marble

[2][3] The localized geology created a marble that is 99.5% pure calcite, with a grain structure that gives a smooth texture, a homogeneous look, and a luminous surface.

It is these qualities for which it was selected to clad the exterior of the Lincoln Memorial and a variety of other buildings throughout the United States, in spite of being more expensive than other marbles.

The Leadville within the Yule area was transformed by contact metamorphism that occurred during the latest Eocene and Oligocene epochs (34 to 28 million years ago) associated with the intrusion and uplift of the nearby granitic Treasure Mountain Dome.

[9] This local contact with the heat and pressure from the intrusion of hot granitic magma recrystallized the Leadville Limestone into a distinctive white marble.

[2][3][10] This local geological activity resulted in a type of marble that is 99.5% pure calcite, with trace amounts of non-calcite inclusions (mainly quartz), and has a density of 170 pounds per cubic foot (2,700 kg/m3).

Quarrying in this high altitude environment with steep slopes, deep snow, and snow-mud slides is so expensive that advances in technology have not been able to overcome the challenges.

In 1931, the 56-ton (55.86 metric ton) block for the die section (on which six wreaths, three Greek figures, and the inscription were carved) was the largest single piece of marble ever quarried at that time.

The companies had different degrees of development and success with the quarry of John Osgood obtaining a major contract in 1895 to supply 140,000 square feet (13,000 m2) of marble for the new state capitol in Denver, Colorado.

The operation showed the unrealized promise of the previous 20 years with a 10-year boom in which marble was shipped to the east and west coasts with contracts reaching one million dollars.

The 1905 problems of transporting marble out of the town have been largely solved (by road and trucks) but the high costs of working in a mountain environment still exist today, and there have been several operator changes with the last one in 2010.

Finished marble was moved into railroad cars of the CYMC-built Crystal River & San Juan Railway (CR&SJ) for shipment throughout the country.

[3][5] Building the CR&SJ solved a major problem of no viable transportation to move large quantities of the stone out of Marble.

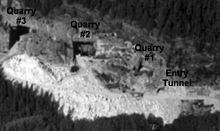

When Quarry 2 cutting started, none of the workers wanted to hang off the edge of the cliff sitting on a wooden bench attached to an overhead derrick.

So the company president, Channing Meek, came up to the quarry, sat on the wooden bench, was lowered over the mountainside, and started cutting marble.

Below the boiler house area near the bottom of the photo is the Pea Vine (winch-cable powered carts on rails) used to move marble from the quarry to the loading station several hundred feet away, where it was placed on wagons for transport to the mill site.

To provide the needed electricity, the company built a hydro-electric plant with the generators located just east of the town limits and completed in July 1907.

[3] Cutting a block involved a channeling machine (consisting of several drill bits and powered by electricity or steam) that made vertical holes from the top down.

The company railroad then transported the marble 28 miles (45 km) north to Carbondale, Colorado, where the cars were connected to other railway trains.

The block is then rigged for lifting by forklift and placed on a haul truck and driven out of the mountain and down to the staging area on the grounds of the old mill site.

The first major contract came in late October 1907 to supply $500,000 worth of marble for the Cuyahoga County Court House, in Cleveland, Ohio, and set off a quarrying boom.

In spite of the financial difficulty orders kept coming in with the first contract of one million dollars for the Equitable Building, New York City, in August 1913 for 1,200,000 square feet (110,000 m2) of marble.

[3][5] As the quarry boomed, so did the town reaching its population peak from 1912 through 1914 of 1,400 to 1,500 residents, including a large number of skilled Italian marble worker immigrants with most of them in the mill site.

Colonel W. W. Harts, the US Army Engineer Officer in charge of Public Grounds and overseer of the project, commissioned geologist George Perkins Merrill to make a determination.

Yet Secretary of War Lindsley Garrison called for testing by Bureau of Standards which gave a positive report on the use of Yule marble.

[3][5][30] The bust came barely one month after the final June 1916 shipment of marble for the Lincoln Memorial when the company went into receivership on 18 July 1916 and ceased operations 15 April 1917.

Assembly started in September but after the base piece was put in place, imperfections were discovered halting the work until a replacement was received.

Riding in the truck was Elmer Bair, the 1931 motorman of the lead electric tram that brought down the body block for the Tomb of the Unknown Soldier in February 1931.

[5][22] Shortly after assembly of the Tomb was completed on 9 April 1932, cracks developed in the main block (wreaths, Greek figures and the inscription) and grew longer over time.

[35] While ANC was studying the situation, a donated replacement block was provided by George Haines, a retired entrepreneur and car dealer in Glenwood Springs, Colorado.

Marble ranged from a single item (such as the baptism font now in the Episcopal church in Glenwood Springs, Colorado) to entire exteriors.