Airbus A350

[5] On 16 September 2004, Airbus president and chief executive officer Noël Forgeard confirmed the consideration of a new project during a private meeting with prospective customers.

Fuel efficiency would improve by over 10% with a mostly carbon fibre reinforced polymer wing and initial General Electric GEnx-72A1 engines, before offering a choice of powerplant.

[5] The original A350 design was publicly criticised by two of Airbus's largest customers, International Lease Finance Corporation (ILFC) and GE Capital Aviation Services (GECAS).

Airbus's then-CEO Gustav Humbert stated, "Our strategy isn't driven by the needs of the next one or two campaigns, but rather by a long-term view of the market and our ability to deliver on our promises.

In 2010, after low-speed wind tunnel tests, Airbus finalised the static thrust at sea level for all three proposed variants to the 74,000–94,000 lbf (330–420 kN) range.

[44] In April 2007, former Airbus CEO Louis Gallois held direct talks with GE management over developing a GEnx variant for the A350 XWB.

[45][46] In June 2007, John Leahy indicated that the A350 XWB would not feature the GEnx engine, saying that Airbus wanted GE to offer a more efficient version for the airliner.

[47] Since then, the largest GE engines operators, which include Emirates, US Airways, Hawaiian Airlines and ILFC have selected the Trent XWB for their A350 orders.

[83] On 1 August 2017, the EASA issued an airworthiness directive mandating operators to power cycle (reset) early A350-900s before 149 hours of continuous power-on time, reissued in July 2019.

[90] The 60.45 m (198.3 ft)-long A350-800 was designed to seat 276 passengers in a typical three-class configuration with a range of 15,270 kilometres (8,245 nmi; 9,488 mi) with an MTOW of 259 tonnes (571,000 lb).

[123] At the 2017 Paris Air Show, the concept was shelved for lacking market appeal and in January 2018 Brégier focused on enhancing the A350-900/1000 to capture potential before 2022/2023, when it would be possible to stretch the A350 with a new engine generation.

[124] In October 2017, Airbus was testing extended sharklets as part of the upcoming performance improvement package (PIP), which could offer 100–140 nmi (185–259 km; 115–161 mi) extra range and reduce fuel burn by 1.4–1.6%.

[131] Also there are improvements to the aircraft’s take off performance by introducing software evolutions which regulate the slat and flap positions, and has also implemented a faster landing gear retraction cycle – conferring greater obstacle clearance and reduced aerodynamic drag.

[133] In November 2019, General Electric was offering an advanced GEnx-1 variant with a bleed air system and improvements from the GE9X, developed for the delayed Boeing 777X, to power a proposed A350neo from the mid-2020s.

[137] The airframe is made out of 53% composites: CFRP for the empennage (vertical and horizontal tailplanes), the wing (centre and outer box; including covers, stringers, and spars), and fuselage (keel beam, rear fuselage, skin, and frame); 19% aluminium and aluminium–lithium alloy for ribs, floor beams, and gear bays; 14% titanium for landing gears, pylons, and attachments; 6% steel; and 8% miscellaneous.

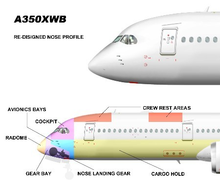

[150] The new nose, made of aluminium,[151] improves aerodynamics and enables overhead crew rest areas to be installed further forward and eliminate any encroachment in the passenger cabin.

[164] The manufacturer has extensively used computational fluid dynamics and also carried out more than 4,000 hours of low- and high-speed windtunnel testing to refine the aerodynamic design.

[140] The wings are produced in the new £400 million (US$641M), 46,000 m2 (500,000 sq ft) North Factory at Airbus Broughton, employing 650 workers, in a specialist facility constructed with £29M of support from the Welsh Government.

[168] Airbus devised a three-pronged main undercarriage design philosophy encompassing both four- and six-wheel bogies to stay within pavement loading limits.

24 was delivered with 80 kg (176 lb) lighter Saft Li-ion batteries and in June 2017, fifty A350s were flying with them and benefiting from a two-year maintenance schedule instead of NiCd's 4–6 months.

Parker also provides hydraulic power generation and distribution system: reservoirs, manifolds, accumulators, thermal control, isolation, software and new engine- and electric motor-driven pump designs.

[180][181] Airbus says the cockpit design allows for future advances in navigation technology to be placed on the displays plus gives flexibility and capacity to upload new software and to combine data from multiple sources and sensors for flight management and aircraft systems control.

For the updated A350 XWB, GE offered a 87,000 lbf (390 kN) GEnx-3A87 for the A350-800/900, but not a higher thrust version needed for the A350-1000, which competes with the longer range 777 powered exclusively with the GE90-115B.

Airbus issued service bulletins regarding onboard equipment and removed galley inserts (coffee makers, toaster ovens) because of leaks.

[203] In November 2021, Reuters found that Finnair, Cathay Pacific, Etihad, Lufthansa and Air France had also complained of paint damage as early as 2016.

A proposed A350−900R extended-range variant was to feature the higher engine thrust, strengthened structure, and landing gear of the 308 tonnes (679,000 lb) MTOW -1000 to give a further 800 nmi (1,500 km; 920 mi) range.

[220] In early November 2017, Emirates committed to purchase 40 Boeing 787-10 aircraft before Airbus presented an updated A350-900 layout with the rear pressure bulkhead pushed back by 2.5 ft (1 m).

[248] The A350 Type Certificate Data Sheet includes MTOWs of 210, 217, 235, 240, 250, 255, 260, 268, 272, 275, 277, 278, 280 and 283 t.[112] The A350-1000 (ICAO code: A35K) is the largest variant of the A350 family at just under 74 metres (243 ft) in length.

[255] It features an automatic emergency descent function to around 10,000 ft (3,000 m) and notifies air traffic control if the crew fails to respond to an alert, indicating possible incapacitation from depressurisation.

[265] After a delay due to the COVID-19 pandemic, the decision was confirmed on 2 May 2022, when Qantas placed a formal order for 12 Airbus A350-1000 aircraft for Project Sunrise flights to originally start in 2025.