African Union of Railways

An extension from Tanzania into Rwanda is proposed as standard gauge, though it starts at a station that is already a container transhipment dry port.

Mining railways that carry very large tonnages (> 10,000 metric tonnes per year) are generally standard gauge.

Modern wagons are usually built with draw-gear designed for easy conversion to some kind of centre coupling such as the AAR or SA3.

Dual and multi voltage locomotives and electric multiple units (EMUs) are proven technology.

Africa has great hydro-electric potential to run electric trains with, though this would not happen overnight.

Axle loads vary considerably, depending on the strength of the track, especially the weight of the rails which are generally too light for modern traffic.

Minimum radius also affects heaviest trains, due to tendency to pull wagons off the rails and derail them.

Transnet Freight Rail in South Africa uses Tubular Modular Track in the main Ermelo yard on its 70 million tonnes per annum heavy haul coal export line.

The continuous support provided by Tubular Modular Track increases rails and turnout life by a factor of two and weld life by a factor of ten (compared to conventional and slabtrack offering discrete support for rails).

The Passenger Rail Agency of South Africa (PRASA) uses Tubular Modular Track in stations to ensure fixed vertical alignment between platforms and trains.

Libya started in 2007 building a completely new 1,435 mm (4 ft 8+1⁄2 in) railway system, albeit slowly.

A link across the Sahara to Central Africa, probably Nigeria, would also spur the growth of 1,435 mm (4 ft 8+1⁄2 in) connections, which make use of continuous access to the Middle East, Europe, and even China in the foreseeable future.

High Speed Lines (AIHSRN) The rail link on the Brazzaville–Kinshasa Bridge will be single track.

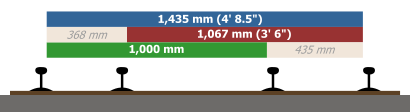

The wide separation or the outer pairs of rails (435 mm and 368 mm) provides space for railclips and suits turnout construction.