Stephenson valve gear

This not only simplified reversing but it was realised that the gear could be raised or lowered in small increments, and thus the combined motion from the “forward” and “back” eccentrics in differing proportions would impart shorter travel to the valve, cutting off admission steam earlier in the stroke and using a smaller amount steam expansively in the cylinder, using its own energy rather than continuing to draw from the boiler.

It became the practice to start the engine or climb gradients at long cutoff, usually about 70-80% maximum of the power stroke and to shorten the cutoff as momentum was gained to benefit from the economy of expansive working and the effect of increased lead and higher compression at the end of each stroke.

Depending on how the gear was laid out, it was possible to considerably reduce compression and back pressure at the end of each piston stroke when working at low speed in full gear; once again as momentum was gained and cutoff shortened, so lead was automatically advanced and compression increased, cushioning the piston at the end of each stroke and heating the remaining trapped steam in order to avoid temperature drop in the fresh charge of incoming admission steam.

American locomotives universally employed inside Stephenson valve gear placed between the frames until around 1900 when it quickly gave way to outside Walschaerts motion.

Launch-type links were pretty well universal for American locomotives right from the 1850s but, in Europe, although occurring as early as 1846, they did not become widespread until around 1900.

On trial, it proved to have no advantage, although in normal service it did gain a reputation as a good performer on banks.

Nevertheless, the fact the link needed to be bodily displaced in order to reverse meant that it required considerable vertical clearance.

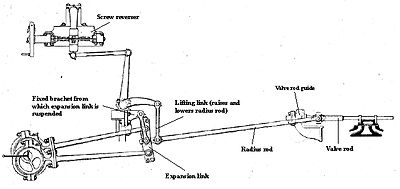

In order to address these problems two main variants were developed: In the Gooch valve gear (invented by Daniel Gooch in 1843) the reversing and cut-off functions were achieved by raising or lowering a radius rod which connected the valve-rod to a "stationary" link pivoting around a fixed point.

The advantages sought were reduced height for the gear and lighter action as the reversing lever was only required to lift the weight of the radius rod.

The reversing and cut-off functions were achieved by simultaneously raising the radius rod and lowering the link or vice versa.