Aluminum building wiring

[1][2] Utility companies have used aluminum wire for electrical transmission in power grids since around the late 1800s to the early 1900s.

Existing homes with this older aluminum wiring used in branch circuits present a potential fire hazard.

[4] While all devices were designed for aluminum during that era, this ended with unification in 1990 when standard Western European equipment became available and the national public owned enterprises (Volkseigener Betrieb) went out of business.

The first 8000 series electric conductor alloy, still widely used in some applications, was developed and patented in 1972 by Aluminum Company of America (Alcoa).

Depending on the annealing grade, AA-8176 may elongate up to 30% with less springback effect and possesses a higher yield strength (19.8 ksi or 137 MPa, for a cold-worked AA-8076 wire).

The AA-1350 aluminum alloy was more prone to problems related to branch circuit wiring in homes due to mechanical properties that made it more susceptible to failures resulting from the electrical devices being used at that time combined with poor workmanship.

The 1977 Beverly Hills Supper Club fire was a notable incident triggered by poorly-installed aluminum wiring.

Aluminum wire is used in residential applications for lower voltage service feeders from the utility to the building.

However, smaller solid aluminum branch circuit wiring is almost never used for residential construction in North America.

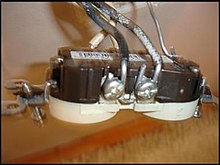

Over time, many of these terminations with solid aluminum wire began to fail due to improper connection techniques and the dissimilar metals having different resistances and significantly different coefficients of thermal expansion, as well as problems with properties of the solid wires.

Larger stranded aluminum wiring with proper terminations is generally considered safe, since long-term installations have proven its reliability.

The use of older solid aluminum wiring in residential construction has resulted in failures of connections at electrical devices, has been implicated in house fires according to the U.S. Consumer Product Safety Commission (CPSC), and in some areas it may be difficult to obtain homeowners insurance for a house with older aluminum wiring.

Unfortunately, CU/AL switches and receptacles failed to work well enough with aluminum wire, and a new specification called CO/ALR (meaning copper-aluminum, revised) was created.

As a result, galvanic corrosion can occur in the presence of an electrolyte, causing these connections to become unstable over time.

COPALUM connectors use a special crimping system that creates a cold weld between the copper and aluminum wire, and is considered a permanent, maintenance-free repair.

As of 2014 there was only one twist-on connector rated or "UL Listed" for connecting aluminum and copper branch circuit wires in the U.S., which is the Ideal no.

These special twist-on connectors have a distinctive purple color, have been UL Listed for aluminum to copper branch circuit wire connections since 1995, and according to the manufacturer's current literature are "perfect for pig-tailing a copper conductor onto aluminum branch circuit wiring in retrofit applications".

Also, the instructions do not mention physically abrading the wires as recommended by the CPSC, although the manufacturer current literature states the pre-filled "compound cuts aluminum oxide".

Some researchers have criticized the UL listing/tests for this wire connector, and there have been reported problems with tests (without pre-twisting) and installations.

[20] These devices are reportedly tested and listed for both AA-1350 and AA-8000 series aluminum wire, and are acceptable according to the National Electrical Code.

[10] Furthermore, just installing CO/ALR devices (switches and receptacles) doesn't address potential hazards associated with other connections such as those at ceiling fans, lights and equipment.