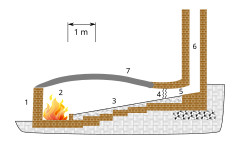

Anagama kiln

An anagama (a Japanese term meaning "cave kiln") consists of a firing chamber with a firebox at one end and a flue at the other.

A continuous supply of fuel is needed for firing, as wood thrown into the hot kiln is consumed very rapidly.

This glaze may show great variation in color, texture, and thickness, ranging from smooth and glossy to rough and sharp.

The largest working Noborigama kiln in Japan is located in Shigaraki, in the southern portion of Shiga Prefecture.

A noborigama is like a set of half-tubes (arches or short vaults, buttressing each other) placed side-by-side with piercings that allow each chamber to feed into the next.

(From a thermodynamic point of view, the higher temperature of combustion and cooler exhaust suggest greater efficiency.)

All of these kilns use two counter-flow exchange mechanisms to maintain the air supply and to change the ware being fired, with minimal loss of heat.

An advantage of the chambered and semi-chambered variants appears to be that they are partly downdraft, which makes the firing results less sensitive to the way the ware is loaded.