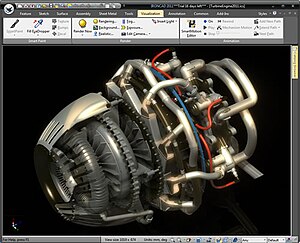

Assembly modelling

Depending on the system, it might be necessary for the users to acquire the latest versions saved of each individual components to update the assembly.

[1]: 242 Components can be positioned within the product assembly using absolute coordinate placement methods or by means of mating conditions.

Mating conditions are definitions of the relative position of components between each other; for example alignment of axis of two holes or distance of two faces from one another.

The final position of all components based on these relationships is calculated using a geometry constraint engine built into the CAD or visualization package.

The importance of assembly modeling in achieving the full benefits of PLM has led to ongoing advances in this technology.