Automatic lubrication system

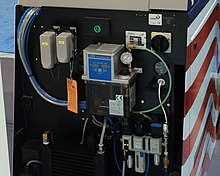

[1] An automatic lubrication system consists of a reservoir with a pump, feed lines, metering valves, and injectors.

The dangers of accessing difficult to reach lubrication points while a machine is running are avoided.

Machines can be running when lubrication takes place, thus decreasing disruption to production.

(Over-lubrication can result in over-heating, spoiled product, damage to bearing seals and a need for extra cleaning.

Factors such as the lubricant consistency, the diameter and length of the feed line and the operating temperature are taken into account.

The cycling of the valve causes the pistons to move back and forth in a cylinder of a specific diameter (bore).

The valve output is a fixed volume however, the amount of time taken for each piston to move back and forth can be varied and pre-programmed.

In this type of system, a central pump station automatically delivers lubricant through a single supply line to multiple branches of injectors.

[16] A dual-line parallel system also uses hydraulic pressure to apply lubricant in measured amounts.