Automotive engineering

The automotive engineering field is research intensive and involves direct application of mathematical models and formulas.

It is an introduction[citation needed] to vehicle engineering which deals with motorcycles, cars, buses, trucks, etc.

While sound can be interpreted as a rattle, squeal, or hot, a tactile response can be seat vibration or a buzz in the steering wheel.

Tests include mileage accumulation, severe driving conditions, and corrosive salt baths.

Cold starts and stalls, RPM dips, idle response, launch hesitations and stumbles, and performance levels all contribute to the overall drivability of any given vehicle.

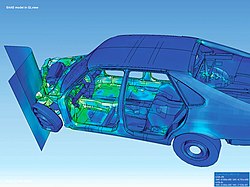

The complexity of components involved in the production process requires a combination of different tools and techniques for quality control.

Therefore, the International Automotive Task Force (IATF), a group of the world's leading manufacturers and trade organizations, developed the standard ISO/TS 16949.

Furthermore, it combines the principles of ISO 9001 with aspects of various regional and national automotive standards such as AVSQ (Italy), EAQF (France), VDA6 (Germany) and QS-9000 (USA).

In order to further minimize risks related to product failures and liability claims for automotive electric and electronic systems, the quality discipline functional safety according to ISO/IEC 17025 is applied.

Along with this, it must also provide an acceptable level of: pedal feel (spongy, stiff), brake system "noise" (squeal, shudder, etc.

), and interaction with the ABS (anti-lock braking system) Another aspect of the development engineer's job is a trade-off process required to deliver all of the automobile attributes at a certain acceptable level.

While some customers are looking for maximum power from their engine, the automobile is still required to deliver an acceptable level of fuel economy.

Other attributes that involve trade-offs include: automobile weight, aerodynamic drag, transmission gearing, emission control devices, handling/roadholding, ride quality, and tires.

Manufacturing engineers are responsible for ensuring proper production of the automotive components or complete vehicles.

They design the machinery and tooling necessary to build the automotive components or vehicle and establish the methods of how to mass-produce the product.

Configuration and performance optimization, system integration, control, component, subsystem and system-level validation of the intelligent systems must become an intrinsic part of the standard vehicle engineering process, just as this is the case for the structural, vibro-acoustic and kinematic design.

In this V-approach, system-level requirements are propagated down the V via subsystems to component design, and the system performance is validated at increasing integration levels.