Bethlehem Steel

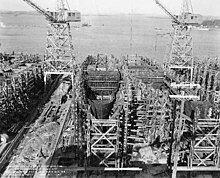

Over 1,100 Bethlehem Steel-manufactured warships were built for use in defeating Nazi Germany and the Axis powers in World War II.

Historians cite Bethlehem Steel's ability to quickly manufacture warships and other military equipment as decisive factors in American victories in both world wars.

In 1982, however, the company suspended most of its steelmaking operations after posting a loss of $1.5 billion, attributable to increased foreign competition, rising labor and pensions costs, and other factors.

The company filed for bankruptcy in 2001 and final dissolution in 2003 when its remaining assets were sold to International Steel Group.

During its early years, the company produced rails for the rapidly expanding railroads and armor plating used by the U.S. Navy.

The nation's decision to rebuild the Navy with steam-driven, steel-hulled warships reshaped Bethlehem Iron Company's destiny.

Following the American Civil War, the U.S. Navy quickly downsized after the end of hostilities as national energies were redirected toward settling the West and rebuilding the war-ravaged South.

By 1881, international incidents highlighted the poor condition of the U.S. fleet and the need to rebuild it to protect U.S. military capabilities, trade, and prestige.

He returned to the United States as Whitworth's agent and, in 1885, was granted an extended furlough to pursue this personal interest.

In 1885, John F. Fritz, sometimes referred to as the father of the U.S. steel industry, accompanied Bethlehem Iron directors Robert H. Sayre, Elisha Packer Wilbur, president of Lehigh Valley Railroad, William Thurston, and Joseph Wharton, founder of the Wharton School of the University of Pennsylvania, to meet with Jaques in Philadelphia.

In the spring 1886, Congress passed a naval appropriations bill that authorized the construction of two armored second-class battleships, one protected cruiser, one first-class torpedo boat, and the complete rebuilding and modernization of two Civil War-era monitors.

By fall 1890, Bethlehem Iron was delivering gun forging to the U.S. Navy and was completing facilities to provide armor plating.

[5] In 1898, Frederick Winslow Taylor joined Bethlehem Steel as a management consultant in order to solve an expensive machine shop capacity problem.

From 1906 until it was delisted in 2002, Bethlehem Steel was traded on the New York Stock Exchange under the two letter symbol BS.

[10] Bethlehem Steel Corporation installed the Gray rolling mill and produced the first wide-flange structural shapes to be made in the United States.

[1] In the 1930s, the company manufactured the steel sections and parts for the Golden Gate Bridge and built for Yacimientos Petrolíferos Fiscales, a new oil refinery in La Plata, Argentina, which was the tenth-largest in the world.

During President Eurico Dutra's presidency in Brazil from 1946 to 1951, Bethlehem Steel received 40 million ton of manganese “for 4 percent of the income of exporting it.” [13] Bethlehem Steel ranked seventh among all U.S. corporations in the value of its wartime production contracts during World War II.

[14] Bethlehem Shipbuilding Corporation's 15 shipyards produced a total of 1,121 ships, more than any other builder during World War II, and nearly one-fifth of the U.S. Navy's two-ocean fleet.

After World War II, female workers were promptly fired in favor of male counterparts.

[17] Following end of World War II, the Bethlehem Steel plant continued to supply a wide variety of structural shapes for the construction trades.

Galvanized sheet steel under the name BETHCON was widely produced for use as duct work or spiral conduit.

Former top manager Eugene Grace failed to adequately invest in the company's pension plans during the 1950s.

As a result, the company encountered difficulty when it faced rising pension costs combined with diminishing profits and increased global competition.

Two years later, in 1997, Bethlehem Steel Corporation ceased shipbuilding activities in an attempt to preserve its steel-making operations.

In 2007, the Bethlehem Steel property was sold to Sands BethWorks, which planned to build a casino where the plant once stood.

[28] The site of the company's original plant in Bethlehem, Pennsylvania is home to SteelStacks, an arts and entertainment district.

SteelStacks currently features the ArtsQuest Center, a contemporary performing arts center, the Wind Creek Bethlehem casino resort, formerly Sands Casino Resort Bethlehem, a gambling emporium, and new studios for WLVT-TV, the Lehigh Valley's PBS affiliate.

[29] The area includes three outdoor music venues: Levitt Pavilion is a free music venue featuring lawn seating for up to 2,500 people, Air Products Town Square at Steelstacks, and PNC Plaza, which hosts outdoor concerts.

On November 9, 2016, a warehouse being used as a recycling facility that was part of the Bethlehem Steel complex in Lackawanna, New York caught fire and burned down.

In 1931 and 1932, Bethlehem Steel manufactured 38 electric multiple unit carriages for the Philadelphia-based Reading Company, then one of the nation's largest and most profitable commercial railroads.