Fore River Shipyard

General Dynamics Quincy Shipbuilding Division, as it eventually came to be known, ended its career as a producer of various LNG tankers and merchant marine ships.

The shipyard traces its beginnings back to 1882, when Thomas A. Watson purchased a farm alongside the Fore River in East Braintree, Massachusetts.

In 1884, Watson attempted to farm the land, but soon realizing that it was a failure, decided to work on a steam engine after he was approached by a local businessman.

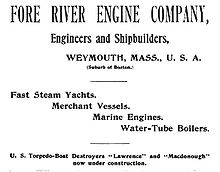

At this point, Watson decided to work with his business partner Frank O. Wellington on ship building, creating the Fore River Engine Company.

[3] The success of this operation was further strengthened the fact that the shipyard was producing a quality engine, and it quickly gained a reputation along the eastern seaboard.

These two ships were the last to be constructed at the East Braintree location, as the yard moved down the river to a site on nearby Quincy Point in 1901.

The Des Moines was launched in 1902 and commissioned in 1904, bringing with it some financial stability to the yard, as new revenues were quadruple those at the East Braintree location.

This was done in order to save costs of having to remove supplies from the trains, transport it over land to Weymouth Fore River, and then float it over to the yard.

Furthermore, the company created the Fore River Apprentice School, in order to ensure that an adequately trained workforce would be able to work at the yard in the coming years.

Despite some possible setbacks, the upcoming 1910 Pan-American Conference, and a guarantee of American participation in the Argentine centennial celebrations, Fore River secured the battleship contracts on 21 January 1910.

[8][A] The maximum price Fore River tendered, $10.7 million, underbid the British by more than $973,000, but their ship's displacement was 2,000 long tons (2,032 t) smaller, the belt armor was 2 inches (51 mm) thinner, and the top speed was slightly slower.

[9][10] Rivadavia was built by Fore River, but they were contractually obligated to subcontract the second ship to a different shipyard in the hope that both would be completed faster, so ARA Moreno was constructed by the New York Shipbuilding Corporation of Camden, New Jersey.

Due to the fact that the United States was officially neutral during World War I, the yard prefabricated the submarines, and then shipped the parts to Canada for assembly.

Located on 70 acres (28 ha; 0.11 sq mi) of land, the yard exclusively built destroyers, with USS Osborne (DD-295) being the last ship constructed at the plant.

Bethlehem also purchased a floating drydock from Simpson’s Dry Dock Company, built a battleship slip, and constructed a new way for merchant ships.

[3] The post-war lull brought about new opportunities for the yard, as it converted or upgraded ships such as SS Minnekahda (1917), and overhauled locomotives for the New York, New Haven and Hartford Railroad.

Much like World War I, the yard expanded, and built the Bethlehem Hingham Shipyard in order to accommodate the increased construction demands.

In an attempt to make sure that riveters would be prevented from defrauding the shipyard of their accurate workload, he scrawled the phrase in chalk on the ships that he was inspecting.

[3] 1962 brought about the construction of SS Manhattan, which was the largest commercial vessel built in the United States at the time, and became the first ship to transit the Northwest Passage to the Alaska North Slope oil fields.

After the end of the strike mentioned above, the yard was accused by the government of overcharging for the first nuclear frigate, USS Bainbridge (CGN-25) and the Long Beach.

J. William Jones, President of the company, stated that the yard was purchased in order to provide its Electric Boat division with increased flexibility.

[3] The addition of modular construction to the yard meant that it could build ships by assembling pre-fabricated units, a technique that was used at the Victory Destroyer Plant during World War I.

[3] The first attempt at government intervention for the yard came with Congressman James A. Burke aiming to stave off the imminent layoffs of two thousand workers.

[31][32] In May 2014, however, it was announced that the Salem would be moved to East Boston after the pier the ship was berthed and closed the previous September due to safety reasons.

The company eventually defaulted on its loans and the property was seized by the United States Maritime Administration in 2000, with its assets being auctioned off a few years later.

[37] As a result of their investigation, on 13 January 2009 the U.S. Occupational Safety and Health Administration imposed fines totalling $68,000 (equivalent to $96,230 in today's dollars).

[4][38] A barge carrying the crane was christened USS Harvey in honor of the fallen worker and left the shipyard on 7 March 2009 en route to Romania.

[41] The earlier incident resulted in an OSHA ruling against Testa Corporation of Lynnfield, Massachusetts, including a proposed $60,400 (equivalent to $94,228 in today's dollars)[4] fine.

[42] Following the 2005 collapse, violations involving improper cleanup and removal of asbestos found in debris left by the accident resulted in a $75,000 (equivalent to $113,354 in today's dollars)[4] penalty imposed against Testa by the Massachusetts Department of Environmental Protection.

[43] The former shipyard served as a port for commuter boats to Boston run by Harbor Express for the Massachusetts Bay Transportation Authority (MBTA).