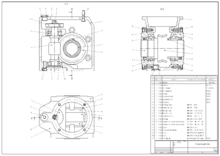

Bill of materials

The first hierarchical databases were developed for automating bills of materials for manufacturing organizations in the early 1960s.

At present, this BOM is used as a data base to identify the many parts and their codes in automobile manufacturing companies.

BOMs are of hierarchical nature, with the top level representing the finished product which may be a sub-assembly or a completed item.

A newer approach, (bottom-up/rules-based structuring) utilizing a proprietary search engine scheme transversing through selectable componentry at high speeds eliminates the planning modular BOM duplications.

[citation needed] The search engine is also used for all combinatorial feature constraints and GUI representations to support specification selections.

Other less frequently used designators for this include "NP" ("no placement", "not placed"), "NF" ("no fit", "not fitting"), "DNM" ("do not mount"), "NM" ("not mounted"), "NU" ("not used"), "DNI" ("do not install", "do not insert"), "DNE" ("do not equip"), "DNA" ("do not assemble"), "DNS" ("do not stuff"), "NOFIT" etc.

The resulting top-level BOM (item number) would include children; a mix of finished sub-assemblies, various parts and raw materials.

In contrast, a single-level structure only consists of one level of children in components, assemblies and material.