Gunpowder

[1][2] Gunpowder has been widely used as a propellant in firearms, artillery, rocketry, and pyrotechnics, including use as a blasting agent for explosives in quarrying, mining, building pipelines, tunnels,[3] and roads.

Nonetheless, it was widely used to fill fused artillery shells (and used in mining and civil engineering projects) until the second half of the 19th century, when the first high explosives were put into use.

Some of it is ejected, wasting propelling power, fouling the air, and generally being a nuisance (giving away a soldier's position, generating fog that hinders vision, etc.).

[15] The first confirmed reference to what can be considered gunpowder in China occurred in the 9th century AD during the Tang dynasty, first in a formula contained in the Taishang Shengzu Jindan Mijue (太上聖祖金丹秘訣) in 808, and then about 50 years later in a Taoist text known as the Zhenyuan miaodao yaolüe (真元妙道要略).

[16] According to the Zhenyuan miaodao yaolüe, "Some have heated together sulfur, realgar and saltpeter with honey; smoke and flames result, so that their hands and faces have been burnt, and even the whole house where they were working burned down.

[22] The earliest chemical formula for gunpowder appeared in the 11th century Song dynasty text, Wujing Zongyao (Complete Essentials from the Military Classics), written by Zeng Gongliang between 1040 and 1044.

[34] However, because al-Rammah attributes his material to "his father and forefathers", al-Hassan argues that gunpowder became prevalent in Syria and Egypt by "the end of the twelfth century or the beginning of the thirteenth".

[38][39] Hasan al-Rammah included 107 gunpowder recipes in his text al-Furusiyyah wa al-Manasib al-Harbiyya (The Book of Military Horsemanship and Ingenious War Devices), 22 of which are for rockets.

[43] Al-Hassan claims that in the Battle of Ain Jalut of 1260, the Mamluks used "the first cannon in history" against the Mongols, utilizing a formula with near-identical ideal composition ratios for explosive gunpowder.

[35] Other historians urge caution regarding claims of Islamic firearms use in the 1204–1324 period, as late medieval Arabic texts used the same word for gunpowder, naft, that they used for an earlier incendiary, naphtha.

[54] The state-controlled manufacture of gunpowder by the Ottoman Empire through early supply chains to obtain nitre, sulfur and high-quality charcoal from oaks in Anatolia contributed significantly to its expansion between the 15th and 18th century.

[66] During this time, European manufacturers also began regularly purifying saltpeter, using wood ashes containing potassium carbonate to precipitate calcium from their dung liquor, and using ox blood, alum, and slices of turnip to clarify the solution.

[67] In Italy, Vannoccio Biringuccio, born in 1480, was a member of the guild Fraternita di Santa Barbara but broke with the tradition of secrecy by setting down everything he knew in a book titled De la pirotechnia, written in vernacular.

Although from a bourgeois family, after his degree in law Lavoisier became wealthy from a company set up to collect taxes for the Crown; this allowed him to pursue experimental natural science as a hobby.

[70] Without access to cheap saltpeter (controlled by the British), for hundreds of years France had relied on saltpetremen with royal warrants, the droit de fouille or "right to dig", to seize nitrous-containing soil and demolish walls of barnyards, without compensation to the owners.

After the end of World War I, the majority of the British gunpowder manufacturers merged into a single company, "Explosives Trades limited", and a number of sites were closed down, including those in Ireland.

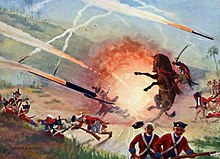

[82] The Mughals began to use bamboo rockets (mainly for signalling) and employ sappers: special units that undermined heavy stone fortifications to plant gunpowder charges.

During the Second Anglo-Mysore War Hyder Ali and his son Tipu Sultan unleashed the Mysorean rockets at their British opponents effectively defeating them on various occasions.

These cannons varied between 180- and 260-pounders, weighing anywhere between 3 and 8 tons, length of them between 3 and 6 m.[97] Saltpeter harvesting was recorded by Dutch and German travelers as being common in even the smallest villages and was collected from the decomposition process of large dung hills specifically piled for the purpose.

[99] According to colonel McKenzie quoted in Sir Thomas Stamford Raffles', The History of Java (1817), the purest sulfur was supplied from a crater from a mountain near the straits of Bali.

[103] It is difficult to accurately translate original Chinese alchemical texts, which tend to explain phenomena through metaphor, into modern scientific language with rigidly defined terminology in English.

[106] To reduce the likelihood of accidental ignition by static electricity, the granules of modern gunpowder are typically coated with graphite, which prevents the build-up of electrostatic charge.

[109] In 1857, Lammot du Pont solved the main problem of using cheaper sodium nitrate formulations when he patented DuPont "B" blasting powder.

In late 14th century Europe and China,[123] gunpowder was improved by wet grinding; liquid such as distilled spirits[66] were added during the grinding-together of the ingredients and the moist paste dried afterwards.

Forming the damp paste into corn-sized clumps by hand or with the use of a sieve instead of larger balls produced a product after drying that loaded much better, as each tiny piece provided its own surrounding air space that allowed much more rapid combustion than a fine powder.

[122] Inappropriately fine-grained powder often caused cannons to burst before the projectile could move down the barrel, due to the high initial spike in pressure.

The standard DuPont Mammoth powder developed by Thomas Rodman and Lammot du Pont for use during the American Civil War had grains averaging 15 mm (0.6 in) in diameter with edges rounded in a glazing barrel.

These products, which should not be confused with smokeless powders, aim to produce less fouling (solid residue), while maintaining the traditional volumetric measurement system for charges.

In the United States, Eleuthere Irenee du Pont, who had learned the trade from Lavoisier, tumbled the dried grains in rotating barrels to round the edges and increase durability during shipping and handling.

[138] The following year (1864) the Gatebeck Low Gunpowder Works in Cumbria (Great Britain) started a plant to manufacture potassium nitrate by essentially the same chemical process.