Frangible bullet

Small particles are slowed more rapidly by air resistance, and are less likely to cause injury or damage to persons and objects distant from the point of bullet impact.

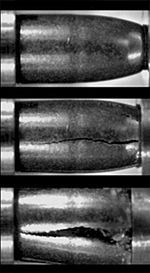

This mechanism has been used to minimize the tendency of malleable lead and copper bullets to ricochet from hard targets as large, cohesive particles.

Mechanical interlocking and cold welding bond the metals together either pressed directly to shape, or into bar stock billets that can be swaged into projectiles, with or without jacketing.

Energy transfer at the point of impact may break brittle targets, and may temporarily soften and permanently deform malleable materials.

Hunting bullets include a frangible core designed to disintegrate when a protective jacket is opened by softer tissue or fluid.

This preliminary study was designed to attempt to establish the validity of claims that these types of rounds pose a potential safety threat to personal body armor.

[3][4] Frangible bullets are also used in reduced ricochet, limited penetration (RRLP) loads intended to reduce risk to friendly forces and innocent persons during close quarters military or police actions in urban areas, aboard ships or aircraft, or in hazardous material environments like oil platforms and chemical or nuclear plants.

[12] In the early 21st-century, the United States military began using frangible bullets to reduce ricochet risk during small arms training.