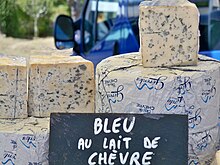

Blue cheese

Blue cheeses vary in flavor from mild to strong and from slightly sweet to salty or sharp; in colour from pale to dark; and in consistency from liquid to hard.

To begin with, the commercial scale production of blue cheese consists of two phases: the culturing of suitable spore-rich inocula and fermentation for maximum, typical flavor.

The addition of modified milk fat stimulates a progressive release of free fatty acids via lipase action which is essential for rapid flavor development in blue cheese.

[13] The next step is coagulation, where rennet, a mixture of rennin and other material found in the stomach lining of a calf is added to solidify the milk further.

[13] Then, the curds granules are knit in molds to form cheese loaves with a relatively open texture.

[10] Next, whey drainage continues for 10–48 hours in which no pressure is applied, but the molds are inverted frequently to promote this process.

[13] In general, the ripening temperature is around eight to ten degrees Celsius with a relative humidity of 85–95%, but this may differ according to the type of blue cheese being produced.

[12] At the beginning of this ripening process, the cheese loaves are punctured to create small openings to allow air to penetrate and support the rich growth of the aerobic Penicillium roqueforti cultures, thus encouraging the formation of blue veins.

[17] Additionally, mycotoxin contamination occurs at low levels and large quantities of cheese are rarely consumed, suggesting that hazard to human health is unlikely.

Curds form, however, due to the function that the enzyme, rennet, plays in removing the hairy layer in the casein micelle.

Rennet is an enzyme that cleaves the κ-casein off the casein micelle, thus removing the strain that occurs when the hairy layer entangles.

Similarly, individual countries have protections of their own such as France's Appellation d'Origine Contrôlée and Italy's Denominazione di Origine Protetta.

[27] Optional ingredients permitted include food coloring to neutralize the yellowish tint of the cheese, benzoyl peroxide bleach, and vegetable wax for coating the rind.

[28] This blue cheese is inoculated with Penicillium glaucum which, during ripening, produces the characteristic of blue-green veins.

[28] In addition to being inoculated with Penicillium roqueforti to give it the blue vein characteristic, research has shown that other microbiota which are relatives of Lactococcus lactis, Enterococcus faecalis, Lactobacillus plantarum, Lactobacillus curvatus, Leuconostoc mesenteroides, Staphylococcus equorum, and Staphylococcus sp.

[32] Some important microbiota contribute to the aromatic profile such as those of the Lactobacillus genus due to their production of volatile compounds.

[33] During ripening, free fatty acids increase in amount which contribute to the characteristic flavor of blue cheeses due to fat breakdown by Penicillium roqueforti.

[28] Its flavors come from the use of unpasteurized sheep's milk, inoculation with Penicillium roqueforti, and the special conditions of the natural caves of Roquefort-sur-Soulzon in which they are ripened.

[35] Similarly to other kinds of blue cheeses, Roquefort's flavor and odor can be attributed to the particular mixture of methyl ketones such as 2-heptanone, 2-pentanone, and 2-nonanone.