Boron nitride nanotube

[5][6] BNNTs have unique physical and chemical properties, when compared to Carbon Nanotubes (CNTs) providing a very wide range of commercial and scientific applications.

[11] BNNTS are packed with physicochemical features including high hydrophobicity and considerable hydrogen storage capacity and they are being investigated for possible medical and biomedical applications, including gene delivery, drug delivery, neutron capture therapy, and more generally as biomaterials [12] BNNTs are also superior to CNTs in the way they bond to polymers giving rise to many new applications and composite materials.

[24] BNNT production route has been a significant issue due to low yield and poor quality in comparison with CNT, thus limiting its practical uses.

significant advancement have been made by Deakin University Australia with a ‘novel and scalable’ manufacturing process will allow the production of BNNTs in large quantities for the first time since the material was first discovered two decades ago.

[18][28] Doping rare-earth atoms of europium turns a BN nanotube into a phosphor material emitting visible light under electron excitation.

[19] Quantum dots formed from 3 nm gold particles spaced across the nanotubes exhibit the properties of field-effect transistors at room temperature.

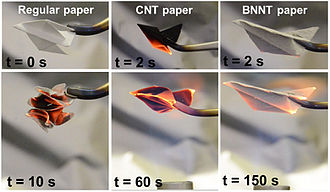

[30] Due to Boron Nitride Nanotubes' stability in both oceanic and atmospheric conditions up to 800°C, they are used in high-temperature applications such as thermal protection systems.

[34] Toxicological[35] investigations on BNNTs in vivo and in vitro showed low toxicity[36] and in general, an enhanced chemical inertia, favoring its biocompatibility.

[39][clarification needed] High stiffness and excellent chemical stability makes BNNTs ideal material for reinforcement in polymers, ceramics and metals.